What’s the Leather Flex Resistance

Leather Flex Resistance is the flex cycles the leather can withstand until discoloring, fuzzing, cracking, decoating, breakage etc. occur.

Instrument – Bally Flexometer

The most common instrument used to determine the leather flexing is the Bally Flexometer.

Clamps are the core parts of this tester, featuring a few pairs of upper clamps and lower clamps in one machine.

Lower clamps are stationary. Upper clamps are movable to and fro through an angle of 22.5 degrees. Its running speed is at 100 ± 5 cycles / min.

For more details on the instrument, please refer to the model AT-L9002 Bally Flexometer on AMADE TECH product unit.

Test Principle of the Leather Flex Test

Two ends of the test piece folded in half lengthwise are respectively mounted in the upper and lower clamps of the bally flexometer.

One clamp is fixed, the other one is movable back and forth at a given angle and a specified frequency to drive the specimen’s movement.

The specimen is examined at regular intervals to evaluate the broken situation.

Significance of the Leather Flex Resistance Test

The leather applied to the footwear is inevitable to be subjected to repeated flexing during walking. Cracking always happens on the grain layer first as the fiber bundle of the grain layer is more fragile than the reticular layer.

The binding fastness of the finish film to the leather body also will decay under the effect of multiple flexing, leading to peeling or decoating.

To some extent, the ability of a piece of leather to withstand the flex reflects its quality.

In our industrial manufacturing field, if we want to produce leather products that meet the quality requirements, we must use professional equipment and a special method to measure the bending resistance of leather raw materials and leather coatings.

The Bally Flexometer is the testing machine you need that can simulate the bending conditions of leather based on ISO 5402 and other more different standards.

Sampling and Conditioning

For dry-flex testing:

Use a press knife to cut six pieces of test pieces by 70 mm in length and 45 mm in width on grain side in the prescribed positions of leather, with the long edges of 3 test pieces parallel to the backbone, the long edges of rest 3 test pieces perpendicular to the backbone.

For wet-flex testing:

Sampling 6 test pieces according to the above method.

Place them in a glass dish(not less than 100 mm in diameter and 25 mm in depth).

Add enough distilled water or deionized water to give a minimum depth of 10 mm.

Put the dish in the desiccator and reduce the pressure to below 4 kPa for 2 minutes.

Restore to normal atmospheric pressure and repeat the pressure reduction and restoration twice.

Remove the test piece and remove excess water using blotting paper, then perform the wet flexing test soonest.

Procedures of the Bally Flex Test

1) Turn on the machine and adjust the bottom ledge of the upper clamp to be horizontal to the upper edge of the fixed lower clamp.

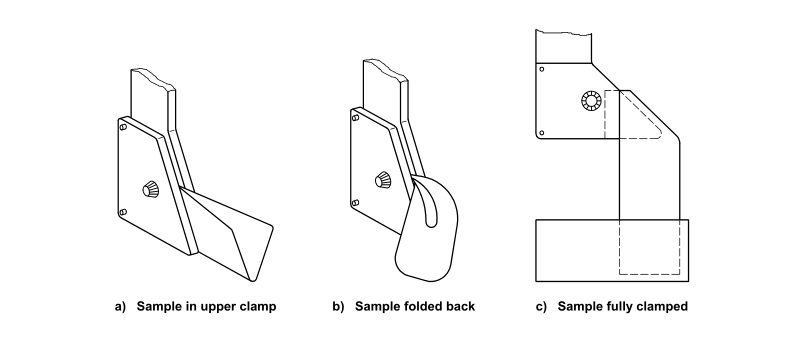

2) Fold the test piece in half along the lengthwise centerline with the grain surface to be tested inwards, so that the two longer edges are brought together. Clamp the folded test piece as shown in the picture with the folded edge against the ledge of the upper clamp and the end against the stop of the clamping screw.

3) Drag the free corners outward and downward around the upper clamp to bring the interior surfaces together, and insert them into the lower clamp vertically to complete fixing, using no more force than is necessary to make the leather just taut.

4) Set the counter to zero and carry out the test based on below flex cycles required:

Dry test: 500, 1,000, 5,000, 10,000, 20,000, 25,000, 50,000, 100,000, 150,000, 200,000, 250,000

West test: 500, 1,000, 5,000, 10,000, 20,000, 25,000, 50,000

During the wet flex testing, remove the wet test pieces from the machine every 25,000 cycles and examine them for exudation before re-wetting them and replacing them in the testing machine.

5) Start the motor and perform the test. Stop the machine once the preset cycles are reached.

6) Remove the specimens from the testing equipment, and examine the broken situation of flexed area (grain side) visually in good light using the naked eye and with a 6-time magnifier. Damage should be recorded, neglecting any damage in the clamped area.

Damages May Occur During the Test

- Change of color of the finish film without damage.

- Cracking or crazing of the finish, the trend of cracking extending through one or more finish layers. The number of cracks may be recorded if possible.

- The abnormal change of abrasion of finish to the leather.

- The abnormal change of abrasion between finish coats.

- The situation of powdering or flaking of the finish coats.

- Colour contrasts shown by finish cracking, powdering or flaking.

The flexed area can be cut for observation If a loose degree of the leather structure needs to be confirmed.

Indications of Test Results

The test report shall include determination way(dry-flex or wet-flex), specimen damage situation such as cracking, color-changing, decorating etc., and the number of flex cycles when damage occurs or without apparent damage within the specified cycles.

Attention

Test pieces can be removed from the machine to examine whether damage occurs during the test, then replace them in the clamps to continue the test.

The position in which the test piece is clamped shall be as same as the original one possible(the marks produced by the clamp can be a guide to help in achieving it.

Some test pieces which become stretched during the test don’t need to be straightened when returning them to the clamps after removed from the testing machine).

If the instrument needs to be suspended for a long time (for example, overnight), test pieces can be left in the clamps but shall keep the test pieces in an incompletely taut state.

Where to Purchase a Bally Flexometer

AMADE TECH is a China Leather Testing Instruments supplier. We offer high quality Bally Leather Flexometer at a Competitive Price. We are proud of our strength with well-trained workers, experienced technicians and mature management policies.

As a professional instrument manufacturer and supplier in China. AMADE TECH is able to provide bally flexing tester with 8 stations, 12 stations or 24 stations to meet different test requirements.

If you have any questions about our products, please feel free to reach us via [email protected].