Rubber Rebound Resilience is a property of reversible deformation under the action of external force.

As we know, rubber is a highly elastic polymer material. It is elastic at room temperature. Under the action of a small external force, it can produce large deformation and can be restored to the original state after removing the external force.

When it returns to its original state, it will also produce a reaction force to the force-applying object simultaneously. Due to the different resilience properties of different rubber types, the magnitude of the reaction force on the force-applying object when rubber is restored to its original state is also different.

The resilience of rubber is proportional to the reaction force on the surface of the object.

We need to use specific values to quantify these properties in actual scientific research and production, so we need a standard testing method and test instrument to achieve them.

ASTM D2632 is a standard that is specifically used to determine the resilience of rubber by vertical rebound.

(Feel free to reach us to get a free ASTM D2632 standard If you are looking for it.)

AT-R7008 Vertical Rebound Resilience Tester Can help you to complete this test.

What’s the Significance of Testing the Resilience of Rubber?

Determining the resilience of rubber is an effective method to master the resilience performance of rubber.

When you do not know how to determine the elastic properties in different materials, you can use the methods in this standard to conduct the test on these materials separately and then use these measured values for comparison to allow you to grasp their performance scientifically.

The test results can guide us in selecting materials that meet the target performance to ensure that the quality of the finished product meets the design expectations.

When researching new rubber formulas, testing the resilience of different rubber formulas is also an important way to understand whether it meets the design requirements.

Note: Since rubber resilience is very sensitive to temperature changes and the depth of the plunger’s penetration, resilience values from one type of rebound tester may not be predicted from results on another type of rebound instrument.

What’s the Principle of the Vertical Rebound Resilience Test?

The top of the plunger is positioned at a height aligned with 100 marked on the scale above the specimen.

The operator releases the plunger, enabling it to slide freely on the vertical rod to fall onto the specimen. The rebound height is visually measured.

Each specimen is tested six times. The first three testings are not recorded, and the subsequent rebound heights of the 4th, 5th and 6th impacts are recorded respectively.

The mean value or the median of these three heights is the resilience value, and the result is expressed as a percentage.

The above is strictly based on ASTM D2632.

What Is the Testing Instrument Used for the Rubber Rebound Resilience Test?

There are usually two instruments available for testing the rebound resilience of rubber. They are Vertical Rebound Resilience Tester and Schob type Pendulum Impact Rebound Resilience Tester.

Here we only introduce the vertical rebound resilience tester, which conforms to ASTM D2632. For details on this instrument, you can visit our AT-R7015 Schob type pendulum impact rebound resilience tester.

Vertical Rebound Resilience Tester

This instrument consists of a base, a stand, a piece of leveling device, four leveling screws, a plunger, a plunger guide, a scale, a viewing window, and so on.

Plunger

The plunger is a metal block resembling an inverted cone with a total weight of 28 ± 0.5 g. Its height is 25.4 mm, and there is a 19 mm diameter protruding ring at the bottom of the cylinder, which is connected to the plunger release trigger.

The plunger has a cylindrical cavity with a diameter of 6.47 mm that penetrates from top to bottom in the middle part. The plunger guide passes straight through this plunger’s cylindrical cavity from the vertical direction.

The top of the plunger aligns with 100 on the scale when you elevate the plunger to the starting point of drop.

The plunger is allowed to rest at the lowest point of stroke and act as a guide to position the rod in the center of the stabilizer, and the height of its drop point is adjustable.

Plunger

Plunger Guide

Plunger Guide

The plunger rod is also called as the Vertical rod. It is a metal rod with a diameter of 6.35mm and a length of more than 400 mm.

It is straight from the top to the end, and any bending is not allowed because it has to ensure that the plunger is able to slide freely on this plunger guide during the test.

The free end of the plunger guide has a sharp point with a diameter of 4 mm and an angle of 60 degrees.

After you mount the specimen, the bottom end of the plunger guide is located against the upper surface of the specimen.

After release, the plunger is guided by this vertical rod to impact the specimen and rebound.

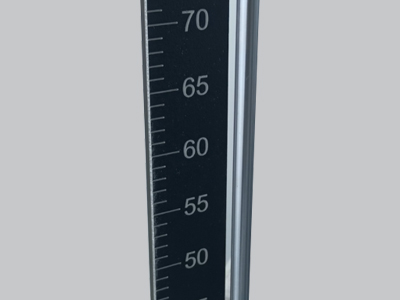

Resilience Scale

The upright scale is marked in 100 equally spaced divisions. Its bottom is flush with the bottom of the plunger guide.

Both are located on the same movable module and can be manually raised together at the same pace.

This ingenious design allows you to adjust the height of the drop point and the height of the resilience scale above the base, so that the drop height always keeps at 400 mm above the specimen surface.

Resilience Scale

Level & Leveling Screw

Bubble Level & Leveling Screws

This rebound resilience test has strict requirements for the perpendicularity of the plunger guide to the base. If you do not put the instrument horizontally during the test, it will cause the plunger to increase friction with the plunger guide during the process of falling and bouncing.

The increase of friction will intensify the resistance of plunger movement, resulting in the measured value of the plunger’s rebound height being smaller than the actual value, which will affect the accuracy of test results.

In order to solve this problem, an omnidirectional bubble level is installed on the base of this instrument. With the aid of 4 leveling screws located in the four corners, you can easily adjust this instrument to a horizontal state.

The method is simple. After placing the instrument on the test bench, you first observe the position of the bubble. If it is in the middle position, it means that the instrument is already in a horizontal state, so there is no need to adjust it.

If it is not at the center, you need to manually turn one or more of the four leveling screws to adjust the height of the base in different directions until the bubble runs to the center of the disc (You need to observe the position of the bubble when adjusting, generally in which direction the bubble is, You find the screw that corresponds to this direction, and then slowly rotate the screw to increase the height).

Viewing Window

Our instrument is equipped with an observation window, which makes it very easy for you to see the height of the plunger’s rebound.

You can move and fix the position of the observation window along the vertical scale.

You are required to make a trial of releasing the plunger to hit the sample to know the estimated rebound height prior to the height adjustment, and then adjust and lock the viewing window.

Viewing Window

How to Prepare Test Specimens?

The required thickness of the specimen is 12.5 mm ± 0.5 mm (0.50 ± 0.02 in).

For the size, there are no hard restrictions. You only have to abide by the rule that the point of plunger impact is not less than 14 mm (0.55 in.) from the edge of the specimen.

We recommend taking a circle with a diameter of 28 mm as the sample.

Prepare three specimens from the same sample

There are 4 methods to obtain the specimens as follows:

- Cut from a Slab of Sample

- Molded

- If the existing sample thickness is not up to the required thickness, Specimens can be prepared by plying samples cut from a slab. You can ply these samples to the thickness required without cementing, keeping the plies smooth, flat, and ensuring an even thickness.

- Cut from finished products and buffed to the required dimensions, ensuring that the opposing faces are parallel and that grain direction is uniform.

How to Calibrate the Vertical Rebound Resilience Tester?

You need to use a mechanical spring calibration device consisting of a spring and a spring receptacle to calibrate this machine.

The force required to compress the spring 3.302 ± 0.0254 mm (0.130 ± 0.010 inches), while mounted in the receptacle, shall be 44.45 ± 0.4445 N (4532.6 ± 45.33 gf).

After the mechanical spring calibration device is mounted into the instrument, do the 3 sets of 5 readings and average each set. Each set becomes a test determination. Average the 3 test determinations to the nearest whole number. This whole number is the resilience calibration value of this instrument.

For more details on the calibration, please refer to the Standard of ASTM D2632.

What’s the Rubber Rebound Resilience Test Temperature?

Normally, you need to condition the instrument and test specimens and carry out the test procedures in the standard laboratory atmosphere as described in practice D618.

If the test needs to be performed at other temperatures, the interested parties concerned need to agree.

What is the Test Procedure of the Vertical Rebound Resilience Test?

How to Calculate the Test Results of Rubber Rebound Resilience?

There are 100 equal divisions in the 400 mm range for the travel of the plunger so that the resilience value can be easily expressed as a percentage.

You need to average the 4th, 5th, 6th test determinations from a specimen to calculate the test result from the specimen.

The final resilience value of the sample can be obtained in either of 2 methods as follows:

- Average the test results from the three specimens to the nearest whole number.

- Find the median of the test results from the three specimens.

What Should Be Included in the Test Report?

You have to list 3 things in the report:

- The average of the 4th, 5th, 6th test determinations of each specimen.

- The average or alternatively, the median of the 3 test results from one same sample.

- If there are any variations from standard test specimens or standard conditions, you need to describe and report them.

Why Do You Choose AMADE TECH as the Vertical Rebound Resilience Tester Supplier?

You may find many suppliers selling this vertical rebound resilience tester all over the world, but AMADE TECH is the manufacturer from China that you can rely on. We have a professional team to design and produce this rubber resilience tester. We are committed to improving the user experience based on customers’ feedback.

Competitive Price

Just because we are from China, we have a natural advantage in cost as a world factory.

If you buy an instrument of the same quality in your home country or other countries, the cost will be doubled or even several times higher.

We are a manufacturer. There is no merchant middlemen to make the difference.

You can enjoy the factory price when you buy here, which will save you a lot of money.

Excellent Quality

Quality is our lifeline.

To ensure that the products delivered to customers are of stable quality, our raw materials are all made of high-quality steel, which is rust-proof, scratch-resistant and corrosion-resistant.

Every part design and all functions meet the requirements of ASTM D2632.

We have well-trained workers and technicians to ensure the accuracy and quality of the assembly.

Every machine is calibrated before leaving the factory.

Abundant Products

We have a rich product line to meet the procurement needs of different customers.

For example, you are in the rubber industry. Apart from buying Rebound Resilience Instrument, you may also need to purchase other instruments. For example, Mooney Viscometer or Moving die Rheometer.

No problem, we can provide you with one-stop services. You don’t need to spend much time and energy on sourcing around the world.

At the same time, you can also enjoy more discounts here.

Reliable After-sales Service

We provide this Vertical Rebound Resilience Tester with an 18-month warranty and lifetime technical support.

It also means that AMADE TECH has enough confidence in the quality of its products. During the warranty period, in case there is a quality problem caused by non-human factors, our technicians will solve it for you free of charge within one working day.

Get in Touch with AMADE-TECH

Many different options are provided for you to establish connections with AMADE TECH.

You can fill out the contact form on this page telling us about your requirements, we will respond within one working day.

In addition, you can also feel free to choose any of below channels:

- Mobile Phone(whatsapp): +86-15989667513

- Wechat: gogo123fish

- Skype: michael.tan 9388

- Email: [email protected]