IPX3/IPX4 Water Ingress Protection Test System

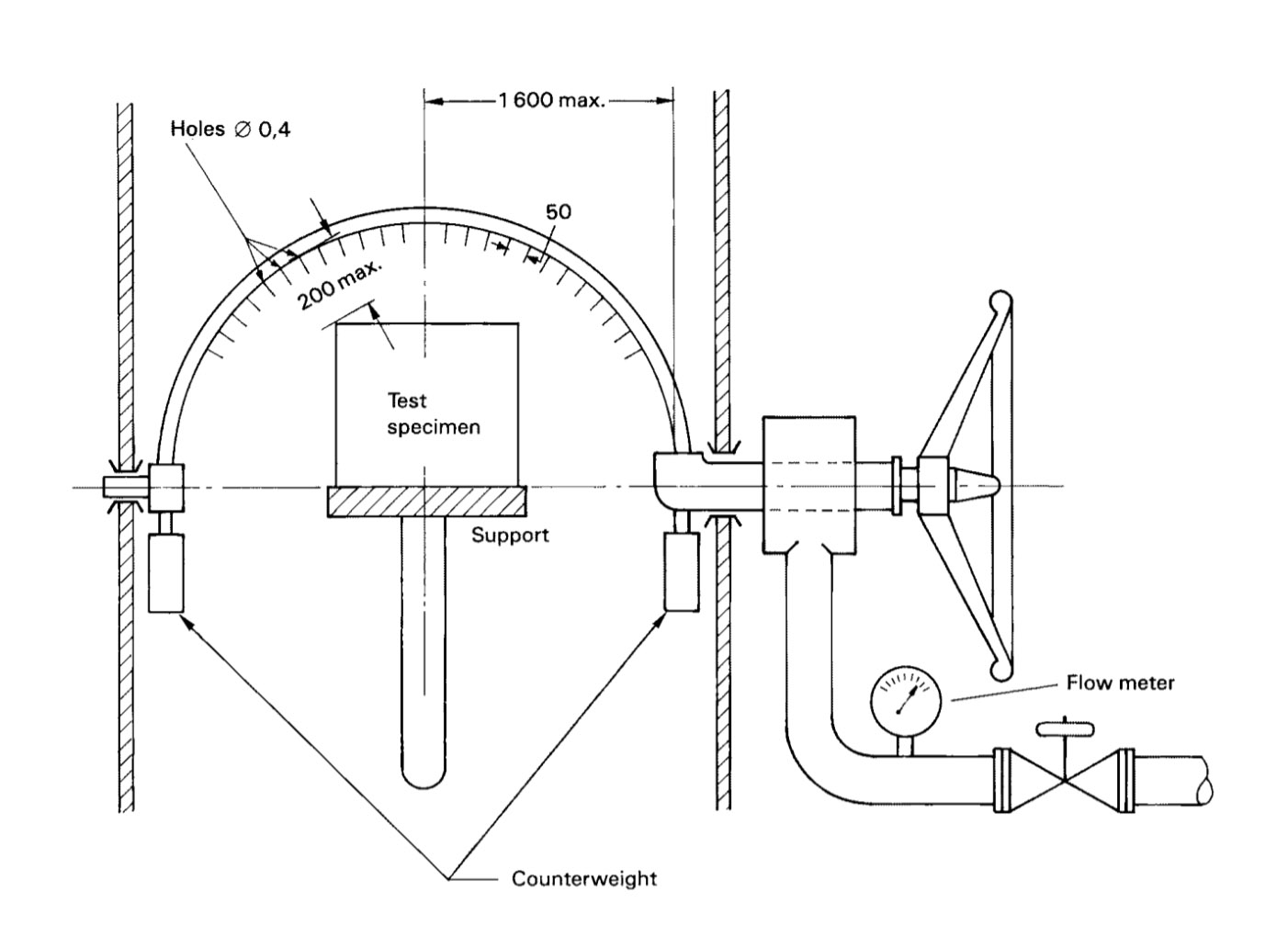

The Open-Type IPX3/IPX4/IPX4K Test Setup is a high-precision system engineered to evaluate enclosure protection against spraying and splashing water. And its core is a semicircular oscillating tube designed to swing at standardized angles and rates. The inner side of the tube features precision-drilled apertures, spaced according to international standards, to deliver a consistent water spray toward the center of the semicircle. By positioning the specimen at this central focal point, users can accurately simulate the environmental stresses required for IPX3 (spraying) and IPX4/4K (splashing) certification.

Unlike enclosed box-type IPX3/4 test device having an enclosed chamber, the open-type configuration offers a simplified design. The system consists of two primary support columns, the oscillating tube, and a central turntable assembly. This “enclosure-free” architecture is particularly advantageous for testing oversized products or for laboratories requiring an unconstrained test area.

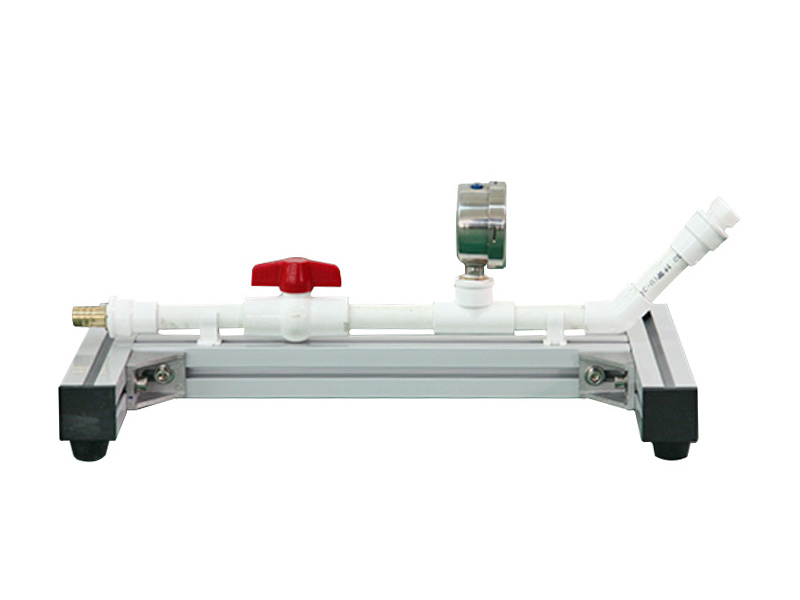

Efficient Water & Power Management

To ensure safety and reliability, the system features a specialized dual-column design that isolates water from electrical components:

- Fluid Management Column: One column houses an integrated water reservoir for immediate supply. It is equipped with a standard inlet for connection to an external water source, ensuring a continuous flow for long-duration testing.

- Electrical Control Column: The opposing column contains the motor, circuitry, and core control systems. This isolated design ensures the total separation of water and electricity, maximizing operator safety and equipment longevity.

IPX3/4 schematic diagram (original from IEC 60529)

Intuitive Interface & Precision Control

The system is managed via an ergonomic control panel located on the column exterior. Users can choose between a high-definition PLC touchscreen or a traditional tactile button controller. The interface allows for:

- Pre-Set Test Ratings: Quick selection of IPX3, IPX4, or IPX4K parameters.

- Customizable Timers: Set and monitor precise test durations.

- Flow Monitoring: An integrated, high-precision flow meter allows for manual or automated adjustment to meet the exact flow rates specified by relevant international standards (such as IEC 60529).

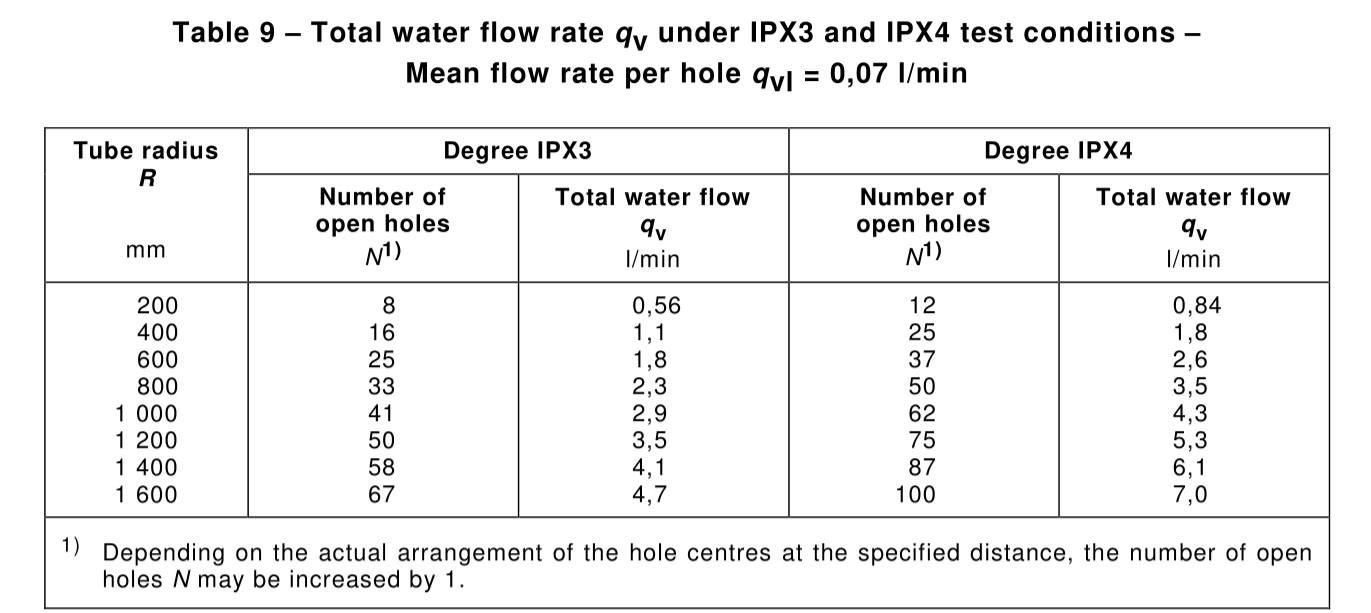

The two support columns are bridged by a high-grade stainless steel oscillating tube (15 mm diameter). This hollow, semicircular component is precision-engineered to provide uniform water distribution. To accommodate a wide range of specimen dimensions, we offer eight interchangeable radii: R200, R400, R600, R800, R1000, R1200, R1400, and R1600 mm.

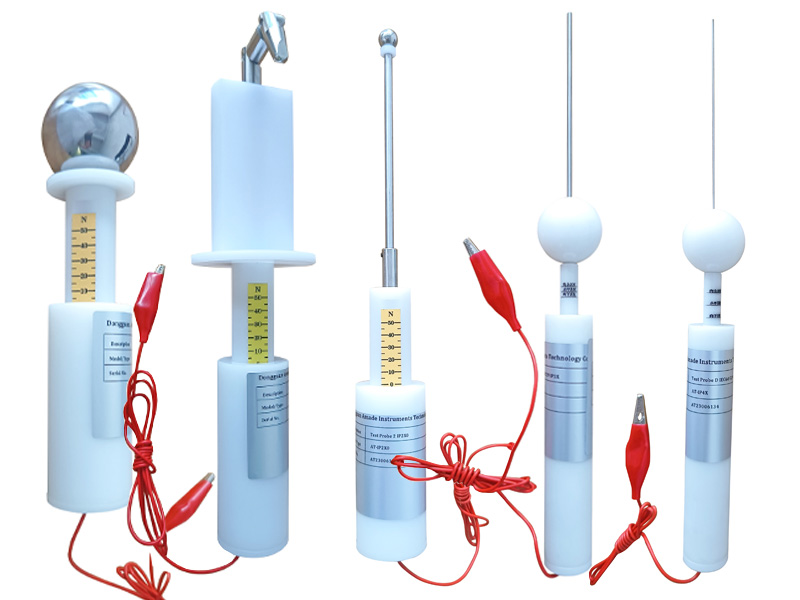

Modular Nozzle System:

Easy Maintenance: Each water outlet is equipped with a detachable, syringe-style needle tip. These are threaded for quick manual assembly, allowing for rapid replacement if a nozzle becomes clogged.

Standard Compliance: The system includes interchangeable needles with 0.4 mm inner diameters for standard IPX3/4 testing and 0.8 mm diameters for high-flow IPX4K testing.

Flexible Configuration: For IPX3 testing, high-quality metal plugs are provided to selectively block nozzles, ensuring the spray pattern meets the required 60° vertical limit.

Needles for IPX3-4-4K tests

Dynamic Motion Control:

Controlled by a high-torque drive system, the tube swivels with extreme precision:

IPX3 Rating: Swings ±60° from the vertical.

IPX4/4K Rating: Swings ±175° (near-total rotation) from the vertical.

Standardized Speed: The system maintains a constant angular velocity of 1 second per 60°, ensuring repeatable and accurate test results.

Oscillating tube specifications (original from IEC60529)

Integrated Turntable & Specimen Support

The turntable assembly is designed for stability and functionality, consisting of a reinforced base, adjustable support rod, and the rotating platform.

Rotational Control: An internal motor provides smooth, bi-directional rotation at a standard speed of 5 RPM (customizable upon request).

High Loading Capacity: The standard turntable supports up to 50 kg, with reinforced custom solutions available for heavier specimens.

Test Under Load (TUL): A built-in waterproof power socket is located at the base of the turntable. This allows samples to be energized during the test, with power integration options that can be synchronized with the main equipment or operated independently.

Mobility: Both the turntable base and the support columns are fitted with heavy-duty industrial casters, allowing the entire setup to be easily repositioned within your waterproof testing facility.

Your Global Partner for Ingress Protection Testing

AmadeTech is a leading provider of comprehensive IP waterproof and dustproof testing solutions. From standard chambers to highly customized open-type setups, we provide the hardware and expertise needed to meet global compliance standards. Contact AmadeTech today for technical consultations and a detailed quotation tailored to your practical testing demands.

Conforming Test Standards

IEC60529, ISO 20653, IEC 60598-1, IEC 60068-2-18, IEC 60034-5, DIN 40050-9, etc

Core Technical Parameters

Model | AT-C1005B-200 | AT-C1005B-400 | AT-C1005B-600 | AT-C1005B1-600 | AT-C1005B1-800 | AT-C1005B1-1000 | AT-C1005B1-1200 | AT-C1005B1-1400 | AT-C1005B1-1600 | |||

Equipment type | Box-type with an enclosed chamber | Open-type | ||||||||||

Oscillating tube radius | R200 mm | R400 mm | R600 mm | R600 mm | R800 mm | R1000 mm | R1200 mm | R1400 mm | R1600 mm | |||

Turntable diameter | Dia. 200 mm | Dia. 400 mm | Dia. 600 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 800 mm | Dia. 800 mm | Dia. 1000 mm | |||

Overall dimensions | (W) 955 x (D) 700 x (H) 1450 mm | (W) 1350 x (D) 1120 x (H) 1770 mm | (W) 1750 x (D) 1550 x (H) 1950 mm | (W) 1950 x (D) 1250 x (H) 1550 mm | (W) 2450 x (D) 1650 x (H) 1950 mm | (W) 2850 x (D) 2050 x (H) 2350 mm | (W) 3200 x (D) 2450 x (H) 2700 mm | (W) 3580 x (D) 2850 x (H) 3100 mm | (W) 4000 x (D) 3250 x (H) 3530 mm | |||

Turntable height range | 150 ~ 250 mm adjustable | 350 ~ 600 mm adjustable | 550 ~ 1000 mm adjustable | 770 ~ 1200 mm adjustable | 1000 ~ 1400 mm adjustable | 1300 ~ 1700 mm adjustable | 1500 ~ 1900 mm adjustable | 1600 ~ 2000 mm adjustable | 1700 ~ 2100 mm adjustable | |||

Spacing of holes | 50 mm | |||||||||||

Number of spray holes | As per specific test requirements | |||||||||||

Hole diamter | Dia. 0.4 mm for IPX3/IPX4, and Dia. 0.8 for IPX4K | |||||||||||

Oscillating angle of tube | ± 60° for IPX3 / ± 180° for IPX4/4K | |||||||||||

Turntable loading capacity | Max. 50 kg or customized | |||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | |||||||||||

Control mode | PLC + 7-inch touch screen | |||||||||||

Feature | Allows energized samples during the test | |||||||||||

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.