IPX1/2 Waterproof Drip Test Apparatus Supplier

The AmadeTech IPX1/IPX2 Test Setup is a precision drip apparatus designed to verify protection against vertical water drips in accordance with international testing standards. Unlike conventional enclosed rain test chambers, AmadeTech’s open-type IPX1 and IPX2 testing equipment features a space-saving design with no size constraints. This makes it the ideal solution for testing large-scale or irregular-shaped samples that won’t fit in standard machines.

Easy Sample Mounting & Observation

This high-performance waterproof testing machine is equipped with a movable turntable with casters for maximum flexibility. Operators can easily mount and secure samples from any direction or even move the turntable away from the machine for easier loading. Once positioned, the turntable aligns perfectly with the drip box to ensure testing accuracy. The enclosure-free design allows operators to monitor the water ingress process in real-time from multiple angles, providing better insights into the product’s waterproof performance. Furthermore, the simplified architecture allows for the cost-effective customization of drip boxes in various sizes to meet specific industrial testing requirements.

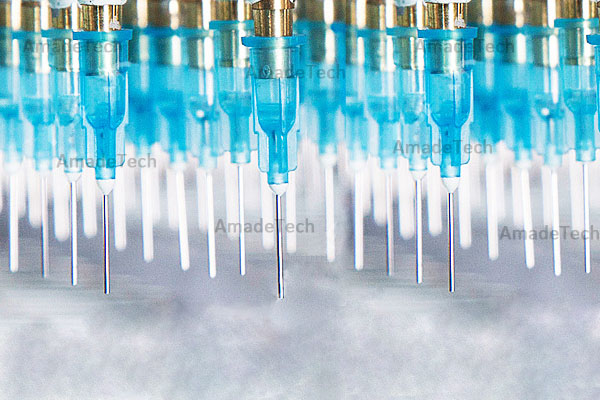

Precision Drip Box Design

The drip box is a container with equal length and width. it has a sealed water tank inside used to temporarily store the water needed to simulate raindrops. There is a water inlet on the top of the drip box connected to a water pipe. Water is continuously supplied through a top-mounted inlet, ensuring a steady flow throughout the IPX1/IPX2 testing process. The bottom of the drip box is engineered with a high-density array of 0.4 mm inner-diameter needles, precision-spaced in a 20 mm grid pattern to meet strict IEC 60529 standards. For maximum operational efficiency, these needles feature a push-in mountable design, making them easy to replace without specialized tools. To ensure workplace safety, a protective mesh guard is installed beneath the needle array, preventing accidental contact and injury during setup or operation.

Dripping needles

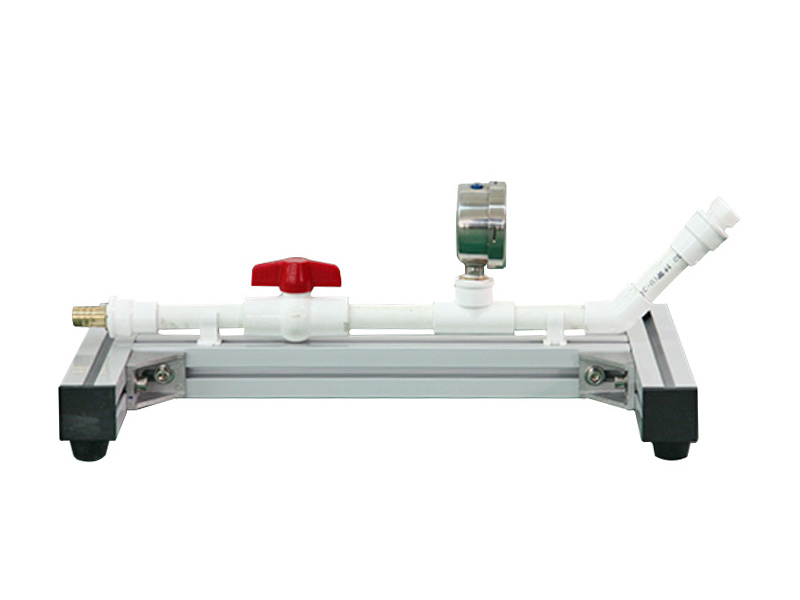

Centralized Control & User-Friendly Interface

Every IPX1/IPX2 test setup is powered by a dedicated control unit that centralizes all water, compressed air, and electrical connections. To protect the precision needles from impurities, the water inlet is equipped with a high-efficiency filtration system, significantly reducing the risk of blockage.

The system is managed via an intuitive HMI touch screen, allowing operators to:

- Control the motorized lifting and lowering of the drip box for precise height adjustment.

- Set and monitor critical test parameters in real-time.

Additionally, a manual flow adjustment valve is conveniently located on the control panel, allowing for fine-tuned calibration of the water flow rate to ensure complete compliance with specific waterproof testing requirements.

Control panel

Flexible Configurations: Wall-Mounted vs. Frame-Type

To accommodate different laboratory layouts, the AmadeTech open-type IPX1 & IPX2 Test Setup is available in two versatile configurations, both supporting fully customizable drip box dimensions:

Wall-Mounted Model: Ideal for laboratories with limited floor space, this version is installed directly onto a vertical wall. The drip box is supported by a robust bracket system and utilizes a precision screw-drive mechanism for smooth vertical movement. For ease of installation, AmadeTech provides pre-drilled mounting holes and all necessary hardware; simply secure the unit to your laboratory wall to begin testing.

Frame-Type Model: This floor-standing version features a high-strength aluminum alloy rectangular frame that supports the drip box and houses the turntable. The vertical position of the drip box is controlled by a high-efficiency electric hoist. Both the frame and the turntable are equipped with heavy-duty casters, offering maximum mobility and layout flexibility within your facility.

Wall mounted IPX1/2 drip tester

Frame-type IPX1/2 drip tester

Wall-mounted drip test equipment

Frame-type drip test equipment

Photoelectric senser and limiting stopper

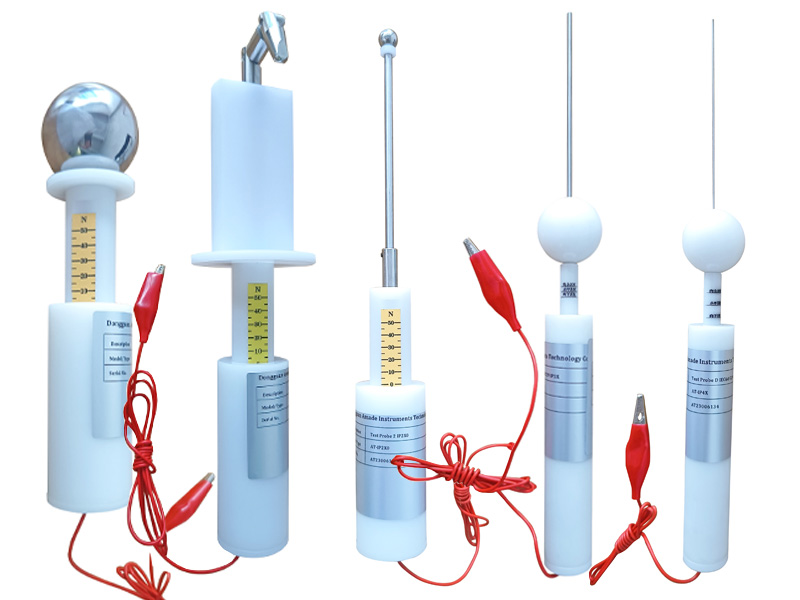

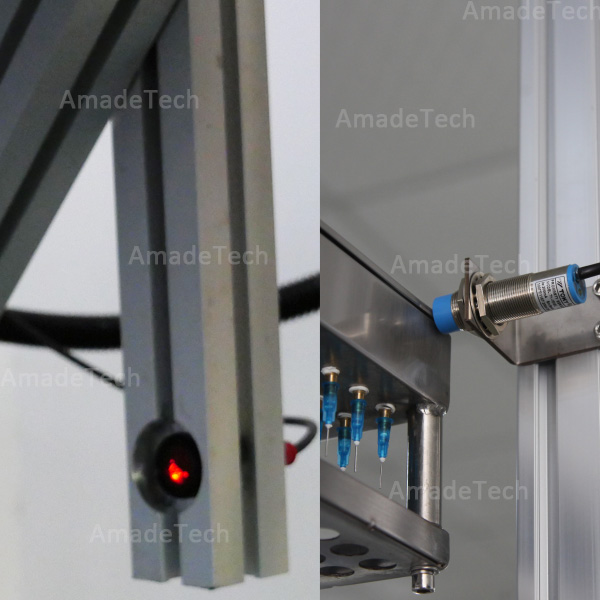

Precision Safety Sensors & Standard Compliance

Regardless of the configuration, every unit is equipped with mechanical limiters and photoelectric sensing technology to ensure equipment safety and testing accuracy.

Collision Protection: Upper and lower limit switches prevent the drip box from accidentally colliding with the sample or the turntable during manual adjustments.

Automated Height Adjustment: To satisfy the 200 mm distance requirement stipulated by IEC 60529 standards, the system utilizes a synchronized photoelectric emitter and receiver. During the automatic descent, the system detects the top of the sample enclosure via a light beam positioned exactly 200 mm below the needles. Once the beam is obstructed by the sample, the system immediately halts the descent, guaranteeing the precise vertical spacing required for a valid test.

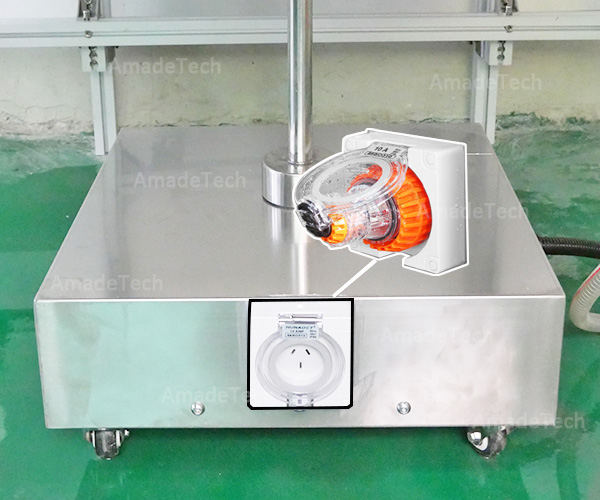

Power socket for samples

Testing for Energized Samples (Live-Circuit Testing)

AmadeTech understands the need for testing samples under load. Our IPX1/IPX2 setups fully support energized sample testing through a dedicated waterproof power socket integrated into the base of the turntable.

Power Versatility: The sample power supply can be integrated with the machine’s main input voltage for consistency or provided via a separate, customized interface for connecting the external power.

Waterproof Connectivity: Each unit includes specialized waterproof adaptor plugs to ensure safe electrical connections during high-moisture testing environments.

Programmable Power Cycles: The intelligent control system allows for both continuous and intermittent power cycling. Operators can program specific intervals (e.g., 30 seconds ON / 30 seconds OFF) to simulate real-world operating conditions and evaluate the electrical safety of the product during water exposure.

Advanced Maintenance: Integrated Air Blowing System

To maximize the equipment’s lifespan and maintain testing accuracy, AmadeTech has integrated a specialized compressed air purging system. At the end of each testing cycle, users can activate the “Blow” function via the control panel. This feature uses pressurized air to drain any residual water from the drip box and needles, preventing the formation of scale, mineral deposits, and dirt that could lead to clogging or corrosion.

Modular Components & Bespoke Customization

At AmadeTech, we understand that every laboratory has unique infrastructure and testing requirements. We offer maximum flexibility by providing both complete systems and individual components. Whether you require a standalone drip box or a high-capacity test turntable rather than a full assembly, we can supply the exact parts you need.

Our engineering team specializes in bespoke IP testing solutions tailored to your specific needs. Simply provide us with your sample dimensions and weight requirements, and we will customize the equipment’s size, load capacity, and mounting configuration to ensure perfect compatibility with your testing environment.

Comprehensive Ingress Protection (IP) Testing Solutions

In addition to our open-type setups, AmadeTech offers a full suite of Ingress Protection (IP) test equipment, including:

Box-Type IPX1/IPX2 Test Chambers: Fully enclosed units for controlled environments.

Full Range of IPX1 through IPX9K Equipment: Solutions for every level of water and dust ingress testing.

As a global provider of high-quality testing instruments, we are committed to helping you achieve compliance with international safety and quality standards.

Contact us today to discuss your specific requirements or to receive a professional consultation and quote for your next project.

Comparison between the Wall mounted, Frame-type and Box-type Drip Test devices

FeaturesVersions | Wall-mounted | Frame-type | Box-type |

Requirements for test site waterproofness | High | High | Low |

Water saving property | Low | Low | High |

Device mobility | Low | High | High |

Ease of mounting the sample | High | High | Medium |

Ease of viewing the sample | High | High | Low |

Integration with other IPX tests | Unavailble | Unavailable | Available |

Device cost | Low | Medium | High |

Conforming Test Standards

- IEC60529

- ISO 20653

- IEC 60598-1

- IEC 60068-2-18

- IEC 60034-5

- DIN 40050-9

Technical Parameters

Model | AT-C1005A2-400 | AT-C1005A2-600 | AT-C1005A-600 | AT-C1005A-800 | AT-C1005A-1000 | AT-C1005A-1200 | AT-C1005A1-600 | AT-C1005A1-800 | AT-C1005A1-1000 | AT-C1005A1-1200 | AT-C1005A1-1600 |

Equipment type | Box-type with an enclosed chamber | Wall-mounted | Frame-type | ||||||||

Drip area | (W) 400 X (D) 400 mm | (W) 600 X (D) 600 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 600 X (D) 600 mm | (W) 800 X (D) 800 mm | (W) 1000 X (D) 1000 mm | (W) 1200 X (D) 1200 mm | (W) 1600 X (D) 1600 mm |

Turntable diameter | Dia. 300 mm | Dia. 400 mm | Dia. 400 mm | Dia. 600 mm | Dia. 600 mm | Dia. 800 mm | Dia. 400 mm | Dia. 600 mm | Dia. 800 mm | Dia. 1000 mm | Dia. 1000 mm |

Overall dimensions | (W) 1050 x (D) 850 x (H) 1550 mm | (W) 1250 x (D) 1050 x (H) 1750 mm | (W) 850 x (D) 950 x (H) 2450 mm | (W) 1050 x (D) 1150 x (H) 2450 mm | (W) 1250 x (D) 1350 x (H) 2450 mm | (W) 1450 x (D) 1550 x (H) 2450 mm | (W) 1150 x (D) 850 x (H) 2450 mm | (W) 1350 x (D) 1050 x (H) 2450 mm | (W) 1500 x (D) 1200 x (H) 2450 mm | (W) 1700 x (D) 1400 x (H) 2450 mm | (W) 1800 x (D) 1800 x (H) 2700 mm |

Spacing of drip holes | 20 x 20 mm | ||||||||||

Drip pinhole | Dia. 0.4 mm | ||||||||||

Drip pan height | Fixed | 800 ~ 1800 mm adjustable | |||||||||

Turntable height | Adjustable | 600 mm (fixed) | |||||||||

Turntable angle | 0° (horizontal) or 15° inclined adjustable | ||||||||||

Turntable loading capacity | Max. 50 kg | ||||||||||

Turntable rotating rate | 1 ~ 5 RPM adjustable | ||||||||||

Control mode | PLC + 7-inch touch screen | ||||||||||

Feature | Allows energized samples during the test | ||||||||||

Open-type IPX1 & IPX2 Test Setup Features

- Premium Construction: The inner chamber is manufactured from high-grade 304 stainless steel to ensure superior corrosion resistance and long-term durability in wet environments.

- Bespoke Customization: Both the drip box dimensions and turntable diameter can be fully customized to accommodate your specific sample sizes and testing requirements.

- Precision Turntable: Features a motor-driven, controllable rotating turntable with a 15° tilt mechanism, specifically designed to meet IPX2 testing requirements.

- One-Touch Motorized Adjustment: The drip box features an automated lifting system, allowing for effortless height adjustment at the push of a button.

- Automated Height Calibration: Equipped with high-precision photoelectric sensors that automatically maintain the standard-mandated 200 mm vertical distance between the needles and the top of the test sample.

- Advanced Control Interface: Integrated HMI touch screen provides an intuitive interface for managing test parameters, monitoring data, and controlling motorized movements.

- Efficient Maintenance: Features quick-change needles for easy replacement and an integrated water inlet filter to improve water purity and prevent needle clogging.

- Internal Self-Draining System: Includes a dedicated air purging (blowing) device to effectively discharge residual water from the drip box, preventing scale buildup and internal contamination.

- Accurate Flow Management: Equipped with precision manual flow meters, allowing operators to easily calibrate and maintain the exact water flow rate required by testing standards.

- Enhanced Safety Protection: Outfitted with adjustable upper and lower limit switches to prevent mechanical collisions and protect both the equipment and the sample.

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.