IPX9K High Pressure and High Temperature Water Jetting Test Set-up

The IPX9K High-Pressure Water Spray Test Chamber is a precision instrument designed to evaluate the ingress protection of equipment subjected to high-pressure, high-temperature water jets. This equipment facilitates the highest level of waterproof testing within the Ingress Protection (IP) rating system, simulating extreme environmental conditions. It is an essential solution for validating the durability of electronics, automotive components, battery packs, and outdoor telecommunications infrastructure.

AmadeTech’s IPX9K chamber provides a fully enclosed testing environment with customizable dimensions to suit specific specimen requirements. The interior is engineered with a specialized spray apparatus and a heavy-duty turntable for comprehensive sample exposure.

Technical Precision and Thermal Control

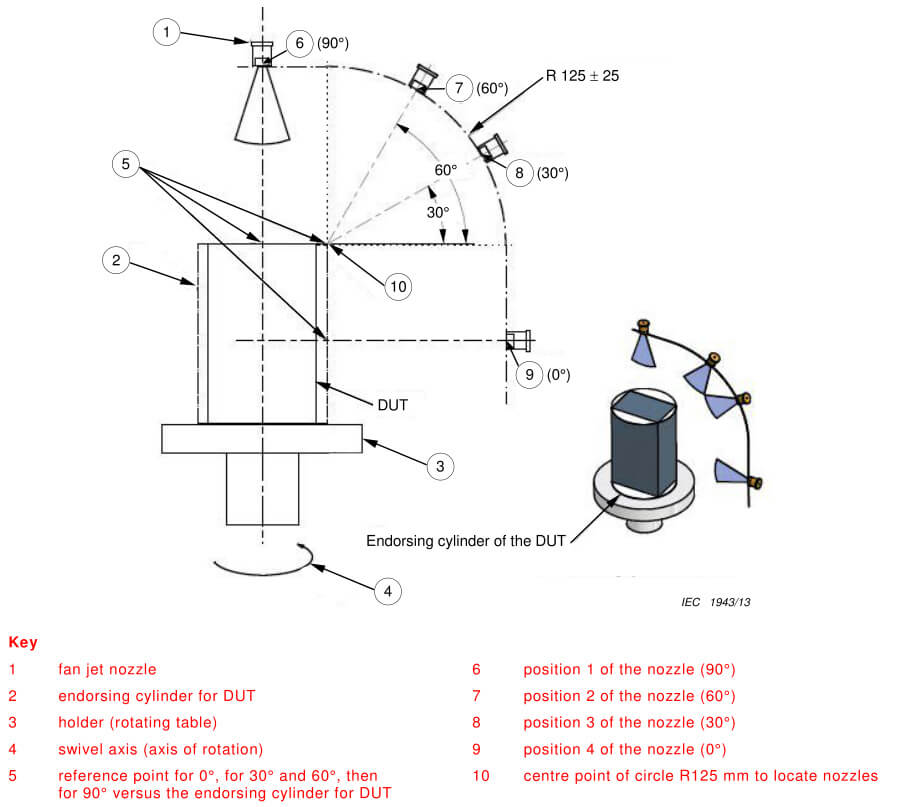

The spray system utilizes four fan-jet nozzles constructed from hardened HRC62 steel. Positioned on a single vertical plane at angles of 0°, 30°, 60°, and 90°, each nozzle is adjustable to maintain the precise required distance from the Device Under Test (DUT).

To ensure thermal accuracy, the reservoir integrates a PID-controlled heating element and temperature probes, maintaining water at a constant (80±5)°C. During operation, water is discharged at pressures between 8,000 and 10,000 kPa at programmed intervals, ensuring rigorous compliance with international standards.

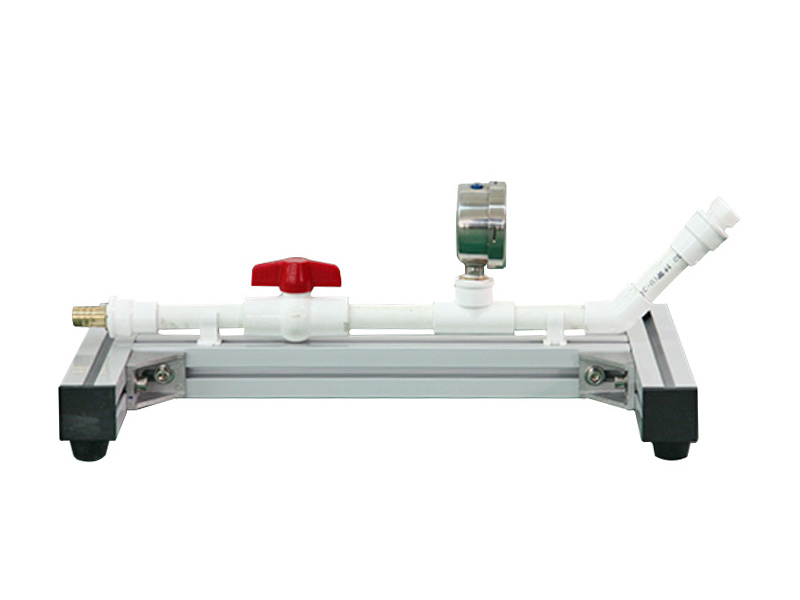

Spray test assemble

Turntable: Fix the Sample Firmly

The integrated turntable supports loads up to 50 kg and rotates alternately clockwise and counterclockwise at (5±1) r/min. This bidirectional motion ensures uniform water distribution across the specimen’s entire surface. The turntable surface includes a grid of mounting points to facilitate the secure fastening of diverse sample shapes.

Water Circulation and Smart Control

To enhance operational efficiency, the AmadeTech IPX9K chamber features an automatic water recirculation system. By continuously recycling water from the collection tank back into the test cycle, the system conserves resources while maintaining thermal stability. The entire process is managed via a 7” PLC-driven touchscreen interface. This programmable controller allows for seamless parameter entry and real-time data monitoring, automatically terminating the cycle upon completion for final specimen inspection.

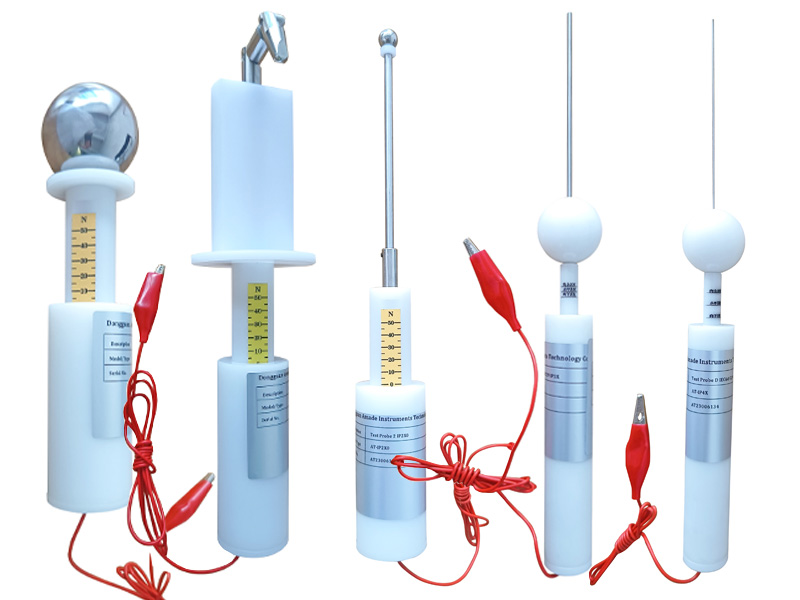

IPX9K spray nozzle

Versatile Open-Type IPX9 Testing Solutions

AmadeTech also provides open-type IPX9 high-pressure test equipment for products that don’t fit in a standard chamber. This open-frame design is perfect for unconventional sizes and shapes, meeting your personalized testing needs without space restrictions. All specifications of The enclosure-free test equipment are IEC60529 standard compliant. Contact us today to learn more about our custom waterproof testing solutions.

Complete Ingress Protection (IP) Testing Range

In addition to IPX9K, AmadeTech offers a full line of IPX1-6 Test Chambers. Whether you need to test for dripping water (IPX1/2), spraying water (IPX3/4), or powerful water jets (IPX5/6), we have the right equipment for your lab.

You can find our full range of IP Testing Equipment HERE.

All-in-One IPX1 to IPX9 Combined Chambers

Looking for a multi-purpose machine? AmadeTech can integrate IPX1, IPX2, IPX3, IPX4, IPX5, and IPX6 ratings into a single IPX9 test chamber.

This integrated approach allows you to perform multiple IP rating tests in one machine, saving you significant floor space and equipment costs.

Test Standards

- IEC 60529

- ISO 20653

- DIN 40050-9, etc.

Technical Specifications

Model | AT-C1005FP-800 | AT-C1005FP-1000 | AT-C1005FO |

Equipment type | Box-type with a chamber | Box-type with a chamber | Open type |

Interior dimensions | (W) 800 x (D) 800 x (H) 800 mm | (W) 1000 x (D) 1000 x (H) 1000 mm | Turntable dia. 800 mm x height 700 mm |

Overall dimensions | (W) 1250 x (D) 1000 x (H) 1755 mm | (W) 1450 x (D) 1230 x (H) 1820 mm | Control cabinet (W) 1420 x (D) 1150 x (H) 1300 mm, Host (W) 700 x (D) 950 x (H) 2900 mm |

Spray angle | 0°, 30°, 60°, 90° | ||

Number of nozzles | 4 | ||

Distance between nozzles and the sample | 100 ~ 200 mm | ||

Water flow rate | 14 ~ 16 L/min | ||

Water temperature | Atmospheric temperature ~ 80 ± 5℃ | ||

Turntable rotation speed | 1 ~ 10 RPM adjustable | ||

Test time | 30 seconds for each angle | ||

Water pressure | 8000 ~ 10000 kPa | ||

Water impact force | 0.9 ~ 1.2 N | ||

IPX9K High Pressure and Temperature Test Chamber Features

- Durable 304 Stainless Steel: The inner chamber and spray assembly are built with premium 304 stainless steel for maximum rust and corrosion resistance.

- Tempered Glass Viewing Window: Easily monitor your waterproof tests through a high-strength tempered glass door.

- Smart PLC Touchscreen Control: Use the 7-inch touchscreen and PLC module to set parameters and view real-time test data instantly.

- Rapid Water Heating: Our high-speed heating system quickly reaches the required temperatures for IPX9K high-pressure testing.

- Flexible Nozzle System: Four fan-jet nozzles are easily replaceable, with fully adjustable spray distances and intervals to meet diverse test standards.

- Customizable Rotating Turntable: Tailor the turntable shape, load capacity, and rotation speed to your specific product requirements.

- Water-Saving Circulation System: Save resources with an automatic water recycling system and an easy-access inlet for tap water connection.

- Advanced Safety Features: Built-in protection against electrical overload, short-circuits, water shortage, and overflow ensures safe laboratory operation.

- Live Product Testing: Designed to safely test energized samples, allowing you to check electrical performance during high-pressure water spray.

Frequently Asked Questions (FAQs)

Leave Your Message Here

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.