IK Impact Testing Machines Supplier

IK Test Equipment is used to determine the level of protection provided by enclosures against external mechanical impacts. The rated voltage of the protected equipment should not be greater than 72.5 kV.

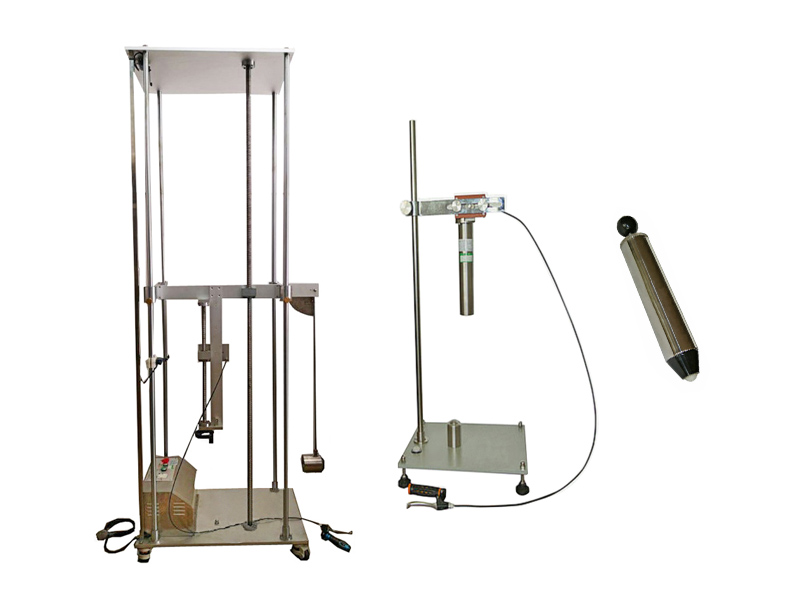

It consists of three types of testing devices: pendulum hammer, spring hammer and vertical hammer. You can select an appropriate one or follow relevant product standard to conduct the test. The enclosure should be mounted on a sufficiently rigid support to reduce displacement during the test, and blows delivered by a striking element of the specified mass are required to be applied to the enclosure. Generally, the number of impacts is 3 per location.

These apparatuses are mainly applicable to mechanical strength testing of housings, operating levers, handles, knobs, indicators, signal lights and lampshades of household appliances, electronic products, lamps and electrical accessories to ensure that the tested products can withstand possible reckless operations and other accidents, so that electrical products can operate safely and reliably.

There is a coding system (IK code) from IK0 to IK1 to indicate the increasing degree of protection from low to high based on the ability of the specimen to resist specified severities of impact. The specific impact energy contains 0.14 J, 0.2 J, 0.35 J, 0.5 J, 0.7 J, 1 J, 2 J, 5 J, 10 J, 20 J even 50 J. These energies can be obtained from our different hammer devices and applied directly to the specimen shells directly according to requirements.

Serial number | IK protection rating | The impact energy that the shell can withstand | Required mass of the striking element |

01 | IK00 | Without protection ability | 0.25 kg |

02 | IK01 | 0.14 J | |

03 | IK02 | 0.2 J | |

04 | IK03 | 0.35 J | |

05 | IK04 | 0.5 J | |

06 | IK05 | 0.7 J | |

07 | IK06 | 1 J | |

08 | IK07 | 2 J | 0.5 kg |

09 | IK08 | 5 J | 1.7 kg |

10 | IK09 | 10 J | 5 kg |

11 | IK10 | 20 J | 5 kg |

12 | > IK10 | 50 J | 10 kg |

Test Standards

IEC 62262, IEC 60068-2-75, GB2423.55, IEC 61439-1, etc

Test Eha: Pendulum Hammer

Our pendulum hammer device adopts a frame structure. A 1000 mm long pendulum arm is hung vertically on the outside of the frame to facilitate hitting the specimen enclosure outward under the influence of gravitational force and its upper end can be rotatable around the pivot. A hammerhead of defined mass and shape is located at the lower end of the pendulum and it is replaceable depending on different severities of impact. The release device hung inside the frame is used to hold the pendulum arm prior to the test and control the occurrence of impact. The impact angle is adjustable and an electric control system is available to control the height of fall from 200 mm to 1200 mm.

| Model | AT-DR1001 |

| Main material | Stainless steel |

| Impact angle | 0 ~ 90° adjustable |

| Pendulum arm length | 1000 mm |

| Striking elements configured | 1.7 kg, 5 kg, 5 kg, 10 kg, each comes with an arm |

| Corresponding impact energy | 5 J, 10 J, 20 J, 50 J |

| Height of fall | 200 ~ 1200 mm electrically adjustable |

| Power supply | AC 220 V 50 Hz / 110 V 60 Hz |

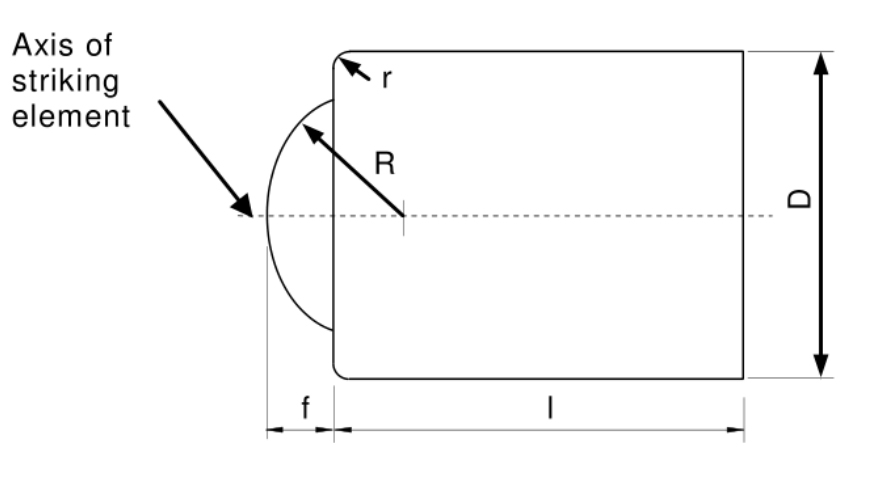

Striking elements

Schematic diagram

Test Ehb: Spring Hammer

Our spring hammer device is similar to a pen and it is mainly made up of 3 parts: body, striking element and release system. The body consists of the housing, the guide for the striking element, the release mechanism and all rigidly fixed parts. The striking element comprises the hammer head, the hammer shaft and the cocking knob. The mass of the striking element assembly is 250 g for energy not more than 1 J or 500 g for energy of 2 J.

| Model | AT-DR1002-A | AT-DR1002-B | AT-DR1002-C |

| Impact energy | One available among 0.2 J, 0.35 J, 0.5 J, 0.7 J, 1 J | 2±0.05 J | Integrated with 0.2 J, 0.35 J, 0.5 J, 0.7 J, 1 J adjustable |

| Tolerance | ±10% | ±5% | ±10% |

| Combined mass | (250±5) g | (500±5) g | (250±5) g |

| Triggering force | ˂ 10 N | ˂ 10 N | ˂ 10 N |

| Total mass | (1250 ± 10) g | (1500 ± 10) g | (1250 ± 10) g |

Test Ehc: Vertical Hammer

Our vertical hammer device also comes with striking elements with different masses complying with requirements. A cylindrical hollow steel tube as the guideway is vertically configured to allow the striking element to fall through it from a specified height on to the specimen surface. The height of fall is adjustable from 0 to 1000 mm and the release action needs to be operated by manual.

| Model | AT-DR1003 |

| Main material | Stainless steel |

| Control mode | Manual |

| Height of fall | 0 ~ 1000 mm adjustable |

| Striking elements configured | 0.5 kg, 1.7 kg, 5 kg, 5 kg, 10 kg, each comes with an arm |

| Corresponding impact energy | 2J, 5 J, 10 J, 20 J, 50 J |

| Weight | Approx. 50 kg |

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade sales engineers will respond within one working day.