Definition and Meaning

The wear resistance of vulcanized rubber is expressed with the abrasion loss of the rubber sample under mechanical friction. This method is called the Akron abrasion method.

Usually, the sample is mounted into an Akron Abrasion Tester. The sample is rubbed against the grinding drum at a certain inclination angle and under a certain load, and the mass change of the sample before and after the friction is weighed. The loss in volume of rubber is calculated, and expressed in cm³/1.61 km.

The abrasion test reflects the abrasion resistance of vulcanized rubber, especially for shoe products.

The wear resistance of rubber is an important factor we consider, which is closely related to the wear life of the sole.

Test Instrument

This test was carried out on an Akron Abrasion Machine.

The Testing Machine Must Meet the Following Conditions

①The rotational speed of the rubber wheel’s rotary shaft is 76 r / min, and the grinding wheel’s rotational speed is 33 ~ 35 r / min.

②When the angle between the rubber wheel shaft and the grinding wheel shaft is 0°, the two shafts should be parallel and level.

③Put a specific load on the load plate to make the rubber wheel bear a 26.7 N (2.72kgf) pressure.

④Under normal circumstances, the angle between the rubber wheel shaft and the grinding wheel shaft is 15°. When the abrasion volume of the sample is less than 0.1cm³/ 1.61 km, you can adjust the inclination angle to 25°, but it should be indicated in the test report.

⑤The diameter of the sample splint is 56 mm, and the working surface thickness is 12 mm.

⑥Grinding wheel specifications for wear test: The abrasive is alumina. And the viscosity is 36. The adhesive is clay. The hardness is medium-hard 2. The size is 150 mm × 32 mm × 25 mm.

Instrument Calibration

The inclination angle of the rubber wheel shaft and the pressure of the grinding wheel on the sample are essential factors that affect the test results. Different inclination angles and different pressures will generate different results.

The greater the angle of inclination, the greater the pressure applied, the greater the wear reduction.

Therefore, a certain inclination angle (such as 15°) and a certain pressure (such as 26.7 N) must be specified so that comparable data measured under the same conditions can be used to judge the wear resistance of vulcanized rubber truly.

In order to meet this requirement, the instrument needs to be calibrated as follows.

①First adjust the test machine base to a horizontal state.

②Adjust the height of the fixed pulley on the calibration frame so that the bottom of the fixed pulley wire groove is on the same horizontal line as the rubber wheel shaft and the grinding wheel shaft, and then wind the wire rope on the grinding wheel. One end of which passes a 2.72 kg weight on the fixed pulley, and the brush that eliminates the rubber chips is in working condition, and the position of the balance mound is adjusted to make the rubber wheel and the grinding wheel appear in a non-connected state.

At this time, the pressure on the sample is 26.7N. Use a test cross level or other angle measuring device to measure the angle between the rubber wheel and the grinding wheel shaft, and adjust it to the angle required for the test, and then fix it with a screw cap.

Sample

The sample is a strip. The length is (D+h) π + (0-5) mm, the width is (12.7 ± 0.2) mm, and the thickness is (3.2 ± 0.2) mm. The surface should be flat without cracks.

Note:

D is the diameter of rubber wheel

h is the thickness of the sample

π is the pi

Test Operation

①Grind both sides of the sample and stick it on the rubber wheel. The bonding should be natural and should not subject the sample to tension. The diameter of the rubber wheel is 68 mm, the thickness is (12.7 ± 0.2) mm, and the Shore hardness is 75 ~ 80 degrees. The diameter of the center hole should be in line with the diameter of the shaft. After sticking, leave it for a period of time to dry the adhesive.

②Fix the rubber wheel with the sample glued on the rotating shaft, and turn on the motor to make the rubber wheel rotate in a clockwise direction.

③Take it off after 15 ~ 20 min of pre-grinding, and weigh it with a balance to the nearest 0.001 g.

④Fix the sample rubber wheel on the rubber wheel rotating shaft for the test, the wear mileage is 1.6km, that is, the grinding wheel of the abrasion machine rotates 3360 r, about 1.5 h, stop and remove the sample rubber wheel, brush off the rubber debris, weigh it within 1 h. The amount is accurate to 0.001 g.

Calculation and Results

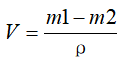

The sample wear volume V (cm³, 1.6kg) is calculated as follows:

where,

m1–the mass of the sample before abrasion, that is, after pre-grinding, g

m2–the mass of the sample after abrasion, g

ρ–The density of the sample, g/cm³

The number of samples is not less than 2, and the arithmetic mean value represents the test result. The allowable deviation is ±10%

Affordable Akron Abrasion Tester for Sale

AMADE TECH is a professional rubber testing instruments manufacturer and supplier from China. It is dedicated to the research, development, production and sales of lab testing equipment.

We supply various rubber testing equipment including the Akron Abrasion Tester with top-level quality in a competitive price. Please fill out below form to contact us to learn more, or directly reach us at [email protected].