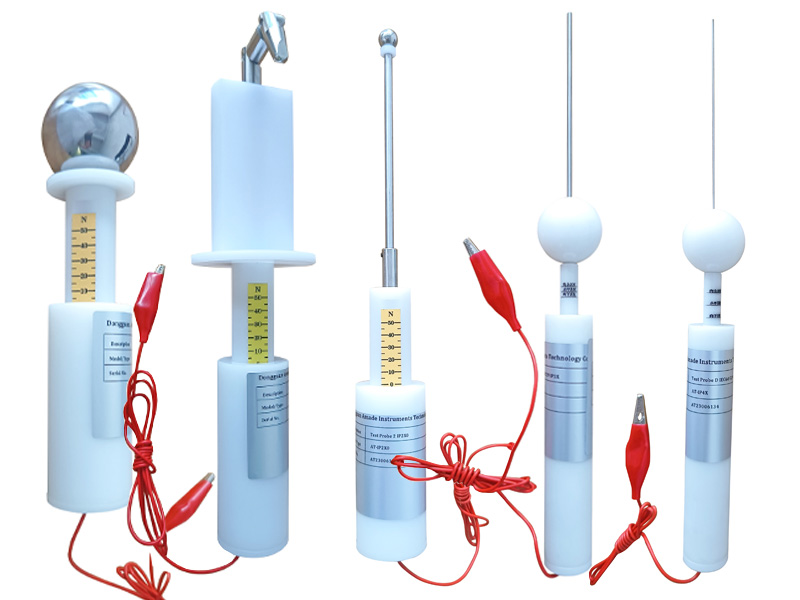

IEC 60529 IPX8 Immersion Pressure Test Tank for Waterproof Testing

The IPX8 Immersion Pressure Test Device is a specialized waterproof tester for simulating water pressure at depths of several meters to tens of meters. The testing process begins by filling the tank with a precise volume of water and fully submerging the specimen. After the lid is securely sealed, the equipment’s high-efficiency pressurization system increases the internal pressure until the preset value is reached. This pressure is then maintained for a specified duration. A sample is deemed IPX8 compliant if no harmful water ingress is detected upon completion of the cycle.

Why Use a Pressure Simulator for IPX8 Testing

According to IPX8 test standards, specimens must undergo continuous immersion under conditions more severe than those defined by IPX7. Since these depths are variable and often impractical to achieve in a standard laboratory setting, the most effective solution is to simulate the corresponding hydrostatic pressure. AmadeTech’s IPX8 immersion pressure test device is engineered specifically to replicate these precise underwater environments accurately.

Structural Advantages of AmadeTech IPX8 Tester

To ensure structural integrity under high pressure, the AmadeTech IPX8 water immersion tester features a tank body constructed from heavy-duty 304 stainless steel. Tank dimensions can be fully customized to accommodate varying specimen sizes.

For larger cylindrical models, we incorporate pneumatic lifting cylinders to facilitate the smooth, automated opening and closing of the lid, significantly improving operational safety and efficiency. The interface between the lid and the tank is secured by a high-performance silicone gasket and eight uniformly tightened bolts, ensuring exceptional pressure retention. Additionally, select models feature an integrated viewing window, allowing for real-time observation of the specimen during testing.

Precision Pressure Control and Automated Testing

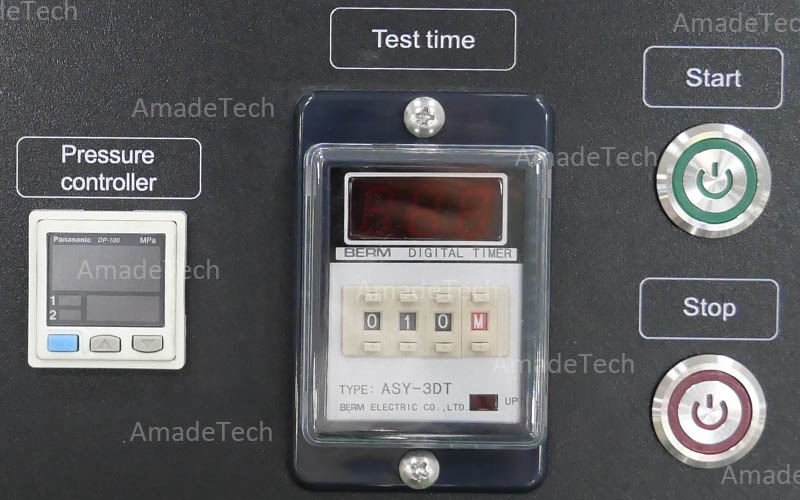

The system integrates a high-precision pressure transducer with a sophisticated control interface. Once the operator defines the target pressure, the equipment automatically regulates the internal environment, achieving and maintaining the specified value for the programmed duration. During this process, the specimen is subjected to constant hydrostatic pressure. If the sample’s structural integrity is compromised, the high-pressure environment forces water into the interior, identifying sealing vulnerabilities. Both real-time pressure levels and elapsed test times are clearly monitored via digital displays on the central control panel.

Control panel

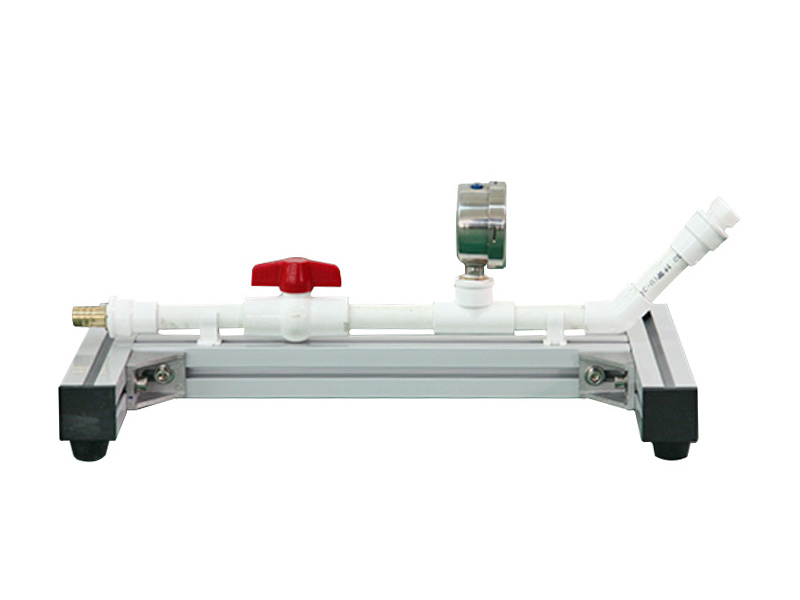

Exhaust valve

Safety valve

Dual Safety Features for Reliable Operation

Operational safety is managed through dual relief mechanisms: a manual exhaust valve and an automatic safety relief valve. The manual valve facilitates rapid depressurization following a test cycle, while the automatic relief valve serves as a critical fail-safe, instantly venting excess pressure should it exceed the equipment’s rated capacity to ensure a secure testing environment.

Visual Leak Detection with Glass Tank IPX8 Testers

In addition to our standard stainless steel models, AmadeTech offers IPX8 test equipment with transparent glass tanks. These units provide a significant advantage for R&D: they allow for visual leak detection. If a specimen is defective, continuous bubble streams pinpoint the exact location of the failure, enabling engineers to identify and rectify design weaknesses more effectively. These glass-tank systems support both positive pressure and negative pressure (vacuum) modes. Specifications, including tank volume and pressure ranges (typically simulating depths of 10 to 50 meters), are fully customizable to meet specific testing protocols.

Please get in touch with AmadeTech specifying your testing requirements on the sample size, required water depth (pressure), and test mode. We will get back to you with an appropriate solution to fit your testing.

If you are interested in more IP Testing Equipment, please feel free to Click HERE to learn more.

Conforming Standards

- IEC 60529

- ISO 20653

- DIN 40050-9, etc.

Technical Parameters

Model | AT-1005E-300-30 | AT-1005E-500-30 | AT-1005E-500-50 | AT-1005EI-600-30 | AT-1005EI-600-50 | AT-1005EA-350-10 | AT-1005EA-350-50 | AT-1005EA-500-10 | AT-1005EA-600-10 |

Interior dimensions | (Dia.) 300 x (H) 300 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 600 x (H) 1200 mm | (Dia.) 600 x (H) 1200 mm | (Dia.) 350 x (H) 400 mm | (Dia.) 350 x (H) 400 mm | (Dia.) 500 x (H) 500 mm | (Dia.) 600 x (H) 1200 mm |

Overall dimensions | (W) 470 x (D) 580 x (H) 910 mm | (W) 600 x (D) 800 x (H) 1050 mm | (W) 600 x (D) 800 x (H) 1050 mm | (W) 780 x (D) 850 x (H) 1750 mm | (W) 780 x (D) 850 x (H) 1750 mm | (W) 800 x (D) 550 x (H) 1000 mm | (W) 800 x (D) 550 x (H) 1000 mm | (W) 880 x (D) 650 x (H) 1180 mm | (W) 1000 x (D) 800 x (H) 1550 mm |

Pressure adjustment range | 0 ~ 0.3 MPa | 0 ~ 0.3 MPa | 0 ~ 0.5 MPa | 0 ~ 0.3 MPa | 0 ~ 0.5 MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.5MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa | Negative pressure -0.05 ~ 0MPa / Positive pressure 0.01 ~ 0.1MPa |

Simulated water depth range | 0 ~ 30 meters | 0 ~ 30 meters | 0 ~ 50 meters | 0 ~ 30 meters | 0 ~ 50 meters | 0 ~ 10 meters | 0 ~ 50 meters | 0 ~ 10 meters | 0 ~ 10 meters |

Applicable IP rating tests | IPX8 | IPX8 | IPX8 | IPX7 & IPX8 | IPX7 & IPX8 | IPX8 | IPX8 | IPX8 | IPX7 & IPX8 |

Tank materials | 3 mm thick 304 stainless steel (20 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | 20 mm thick transparent acrylic (25 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | 10 mm thick transparent acrylic (20 mm thick stainless steel flange) | ||||

Pressure sensor accuracy | 0.001 MPa | ||||||||

Pressure sensor deviation | ± 0.002 MPa | ||||||||

Compressed air pressure required | 0.6 ~ 0.8 Mpa | ||||||||

Protection devices | Pressure safety vlave and leakage switch | ||||||||

AmadeTech IPX8 Immersion Pressure Test Device Features

- Durable 304 Stainless Steel: Built with high-grade, rugged stainless steel to ensure a long service life.

- Tailored Tank Sizes: Custom tank dimensions are available to fit your specific product testing needs.

- Adjustable Depth Simulation: Customize your maximum test depth to meet various IPX8 testing standards.

- Powerful Pressure Management: Features an advanced system for rapid pressurization and stable pressure holding.

- Smart Preset Function: Easily set and save target pressure values and test times for repeatable results.

- Auto-Relief System: The device automatically relieves internal pressure once the test timer reaches zero.

- Optional Pneumatic Lift: Add air cylinders for effortless lid opening and closing, improving workplace safety.

- Reliable Safety Valves: Built-in safety relief valves guarantee absolute security during high-pressure cycles.

- User-Friendly Interface: Simple, intuitive controls make it easy for any operator to perform professional waterproof tests.

FAQs

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. Amade Tech sales engineers will respond within one working day.