IEC 60695-2-20 Hot-wire Coil Tester Supplier

Hot Wire Ignition Test Chamber is designed to simulate the thermal stress caused by a heat source or power source such as a burning element or overload resistor for a short period of time, which is used to determine the resistance to ignition of plastic insulating materials from an electrically heated wire. During testing, the specimen is wound with heater wire and subjected to a constant current. The time required to ignite a test specimen when it is affected by heat can be measured. If the specimen drips, the time at which this occurs is also recorded.

The test equipment is featured with a stainless steel made test chamber having an inside volume more than 0.5 cubic meters, providing a draught-free test area whilst allowing normal thermal circulation of air past the test specimen. The inside wall of the chamber is purely dark achieving an ambient light level not exceeding 20 lux. an exhaust fan is built in the device to extract waste gas produced by combustion as needed. A glass window can be pulled down and up by manual is available at the front of the chamber. It allows you to observe the combustion status inside the chamber during testing. To facilitate the specimen mounting and dismounting, a illuminating light is provided in the chamber.

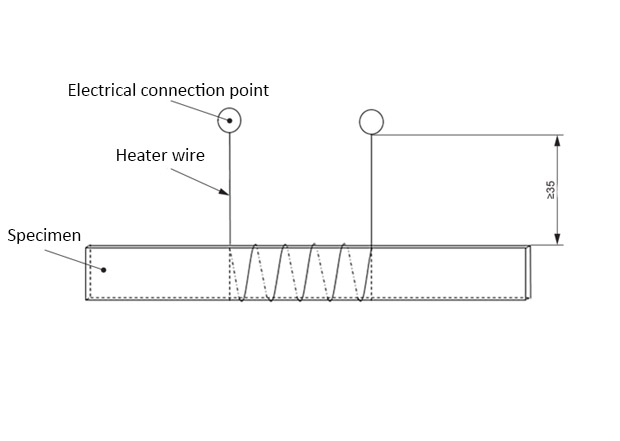

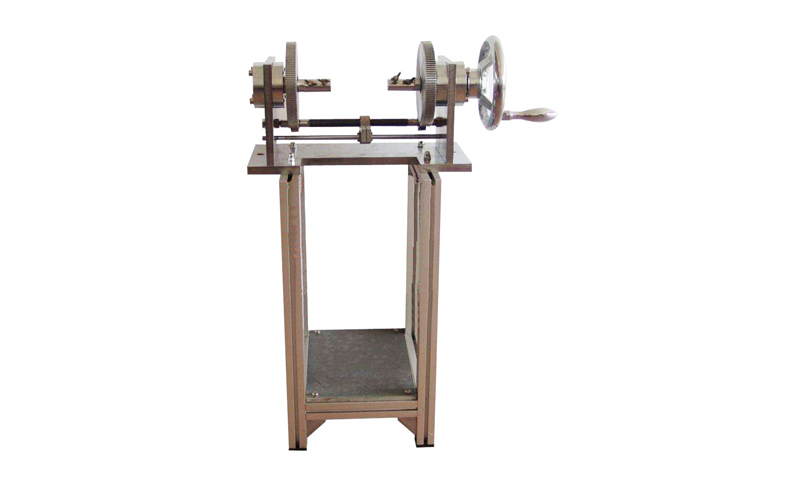

The tester comes with a heater wire made of Nickel and Chromium precisely allocated in the required proportions as per the standards, and its dimensions is 0.5 mm in diameter and 260 mm in length. We will include a special heater wire winding device and a weight with the test apparatus. It allows the the heater wire to be wound around the test specimen centred along the longitudinal axis of the specimen by operating the hand wheel, so as to apply 5.4 N to the five windings distributed at a constant interval of 6.35 mm with a standard weight.

Specimen winding pattern

Heater wire winding device

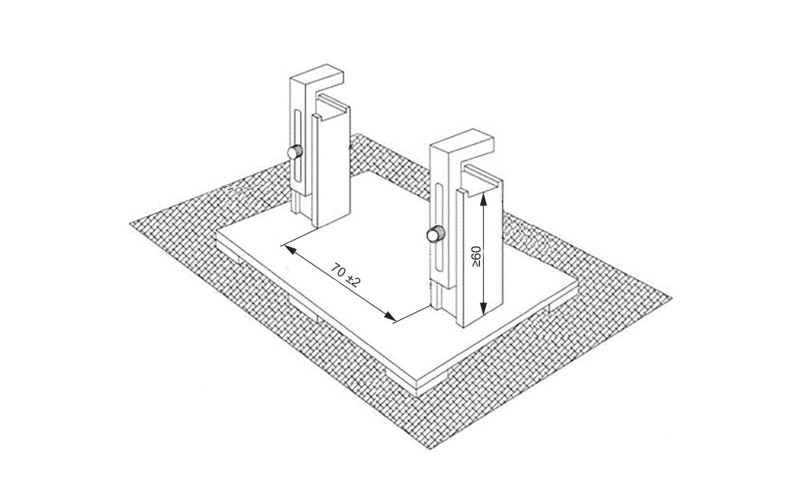

Test fixture of hot wire ignition tester

There is a test specimen fixture at the bottom surface of the chamber to accommodate the prepared specimen. Before test, You need to clamp the two ends of the bar specimen horizontally into the hold-down clamps at the tops of the two supporting posts 70 mm apart, and connect the wires properly.

The test device is fitted with a control panel consisting of physical buttons and digital displays. You follow the specified instructions to press this buttons while observing the test progress during testing, and the results of time to ignite(IT),time to drip(DT) will be appeared on the displays for record easily.

Test Principle

A rectangular bar-shaped test specimen with the center portion wrapped with a coil of heater wire is supported horizontally on a test fixture at both ends. The circuit is energized by applying a fixed power density to the coil of heater wire to heat up the specimen. The behavior of the test specimen is observed for determination of the test result. The ignition time or melt time needs to be recorded if it occurs.

Test Standards

IEC 60695-2-20, UL746C, ASTM D3874, etc.

Technical Parameters

| Model | AT-P6023 |

| Chamber material | SUS 304 stainless steel |

| Inner Volume | Over m3 |

| Heater wire | Φ0.5 mm, Ni/Cr (80%/20%) |

| Wire length | 250 ± 5 mm |

| Heating power | Continuously adjustable not more than 100W |

| Preheating time | 0.1 ~ 999.9 s, ±0.1s (time range adjustable) |

| Test time | 0.1 ~ 999.9 s, automatic recording |

| Auto stop function | After the specimen reaches the preset glow time, the equipment stops working automatically. |

| Exhaust system | Exhaust fan |

| Control panel Language | All in English |

| Mode of operation | Press-button |

| Overall dimensions | W1100mm x D550mm x H1100mm |

| Power supply | 1 phase 220 V 50 Hz or 110 V 60Hz Optional |

| Accessories or Tools | Ø Heater wire: 100 meters

Ø Specimen-winding device 1 pc |

Request a Quote Now

Please feel free to contact us for more details on the product, price, lead time, payment terms, shipment methods, etc. AmadeTech sales engineers will respond within one working day.