In the fields of automotive electronics, charging devices, outdoor equipment, etc., it is crucial to ensure that products can withstand harsh environmental conditions. The IPX9K waterproof rating is one of the most demanding standards. It tests the device’s tolerance to high-pressure, high-temperature water jets. During the test, the water jet is sprayed at different angles at a specified pressure and flow rate. Before the device can be evaluated and certified for waterproofing according to this standard, the water jet impact force of the test equipment must be accurately calibrated in order to obtain accurate test results.

In this article, we will explore the IPX9K water jet impact force calibration procedure using the IPX9K Water Jetting Spray Test Chamber from AmadeTech as an example, emphasizing the importance of calibration, related steps and best practices to ensure reliable and repeatable test results.

Understanding IPX9K and Its Significance

The IPX9K standard is part of the IP (Ingress Protection) rating test and is the highest level of water resistance test, which quantifies the water resistance performance of the device. However, we should not mistakenly assume that a product that passes the IPX9 test will definitely pass the IPX7 and IPX8 immersion tests. This is not true. There is no direct causal relationship between IPX9 and other levels of testing, especially independent of IPX7 and IPX8 testing. Specifically, IPX9K involves water resistance testing with high-pressure, high-temperature water jets sprayed onto the test sample to simulate real-world conditions such as car wash systems or heavy machinery cleaning.

Regular calibration of the water jet impact force ensures that the water jet provides consistent and standardized pressure, thereby accurately evaluating the performance of the device.

Why Is IPX9K Water Jet Impact Force Calibration Important?

Ensure test accuracy

Precise calibration ensures that the force applied by the water jet is within the standard range, resulting in reliable test results.

Repeatability

Standardized calibration procedures allow test equipment to produce consistent test results across different test labs and over time.

Compliance

Regular and correct calibration is often a requirement of certification bodies to confirm compliance with industry standards.

Test equipment safety and durability

Accurate testing helps manufacturers identify potential vulnerabilities, resulting in more durable products.

Calibration Procedure Overview

The IPX9K Water Jet Impact Force Calibration involves several key steps:

Preparing the calibration setup

If you purchased the test equipment from AmadeTech, we can provide a set of water jet impact force calibration device with the machine. The device is small in size and shaped like a small rectangular box. The shell is made of 304 stainless steel with sufficient pressure resistance. At the center point of the upper part of the metal box near one short side, there is a protruding and standing T-shaped small impact plate. Although the device is small, it plays an important role. The plate is 30 mm long and 2 mm thick. The device connected to this small iron plate at the bottom is a force sensor. During calibration, the water from the 90-degree nozzle impacts the small impact plate vertically, and the force sensor at the bottom collects the impact force of the impact plate in real time and displays the value on the human-machine interaction interface. The calibration device is connected to the test equipment via a cable.

In addition, the calibration device also includes a 1N weight for self-calibration of the calibration device.

IPX9K calibration device

IPX9K calibration weight

Establishing water pressure and flow

If the machine is equipped with a manual flow adjustment device, you need to first adjust the machine’s human-machine interface to the manual operation interface, then manually tap on the virtual button on the screen to turn on any nozzle, and then observe whether the flow rate of the flow meter is within the standard flow value. If not, manually rotate the knob of the flow meter to adjust the flow rate to 15±1L/min. The water pressure and flow rate change synchronously. When the flow rate is within the standard range, the water pressure will automatically meet the standard requirements.

Verifying the calibration device

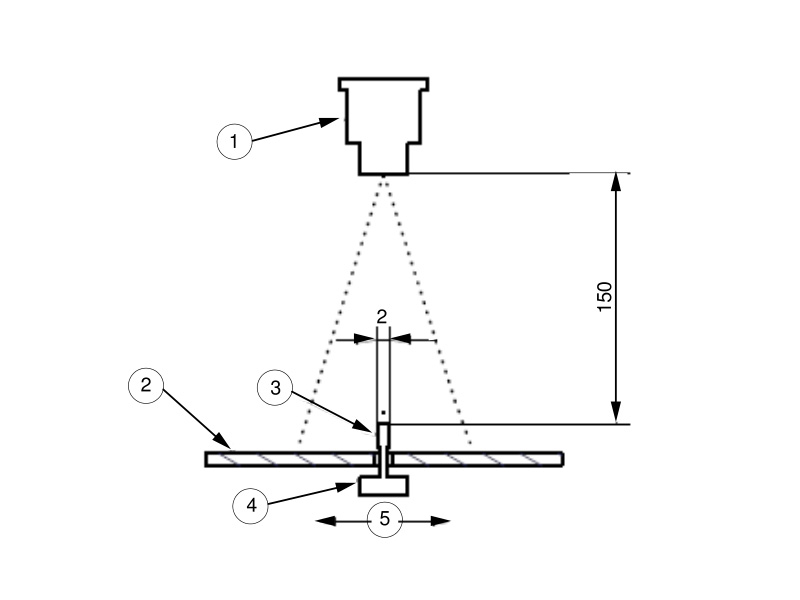

Insert the plug of the calibration device into the socket on the side of the machine cavity, then place the calibration device on the turntable, and use a ruler to measure whether the vertical distance between the 90-degree nozzle and the impact plate of the calibration device is 150mm. If not, adjust the height of the turntable until the spacing of 150mm is met. Measure and adjust the distance between the “T” impact plate and the walls of the inner chamber in the forward and backward direction and in the left and right direction to coincide with the distance between the 90-degree nozzle and the walls, which is to ensure the center point of the impact plate is vertically aligned with the center point of the 90-degree nozzle. After completing the above actions, go to the bottom of the manual operation interface to see if the current force value is 0. If not, press the force reset button.

Slowly place a 1N weight on the T-shaped impact plate so that the groove at the bottom of the weight is stuck on the plate and does not fall off. Then check whether the current force value on the screen is 1N: If it is, it means that the accuracy of the calibration device is normal. If not, contact the supplier for calibration.

Measuring impact force

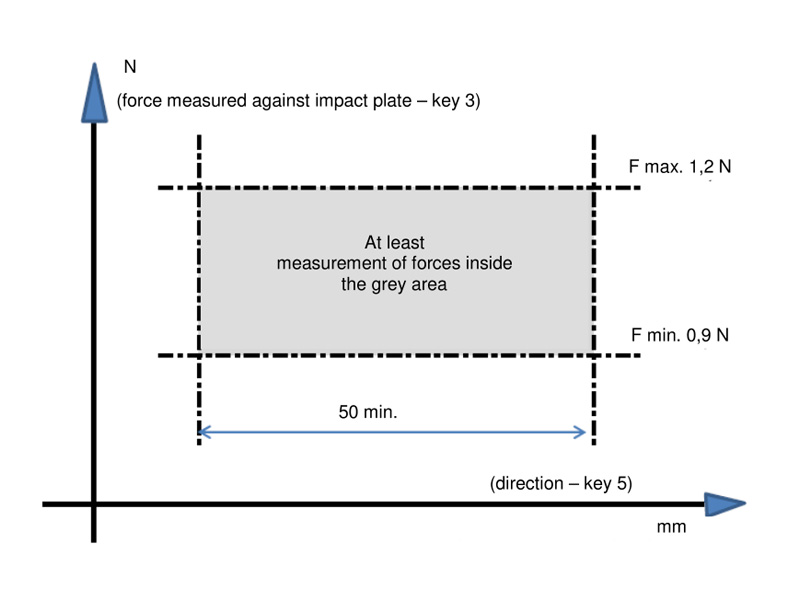

After completing the above actions, remove the weight and close the door of the test chamber. Tap on the 90-degree nozzle button, and then tap on the water pump switch to manually start the water spray. At this time, the water jet of the nozzle will spray directly to the “T”-shaped impact plate, and observe whether the current impact force value at the bottom of the screen is between 0.9N and 1.2N. If the impact force value remains within the standard value range during the calibration period, such as 50 minutes, it means that the water jet impact force is qualified. After the calibration is completed, first tap on the water pump switch, and then tap on the 90-degree nozzle switch.

Adjusting equipment

If the actual impact force value is greater than 1.2N during the recalibration process, you need to change the frequency by decreasing the reference frequency value by 0.1 or 0.2Hz each time, and then start the water pump to observe whether it meets the standard, until the impact force reaches the range of 0.9N to 1.2N.

Similarly, if the actual force value is less than 0.9N, you need to change the frequency by increasing the reference frequency value by 0.1 or 0.2Hz each time, and then start the water pump to observe whether it meets the standard, until the impact force reaches the range of 0.9N to 1.2N. Note that the force value must be reset to zero each time before starting the water pump during the operation.

Documenting calibration results

After IPX9K water jet impact force calibration is completed, you need to record the following data:

Record all parameters, including pressure, flow rate, impact force, and environmental conditions.

Generate calibration certificates for quality assurance and compliance purposes.

Best Practices for Accurate Calibration

To ensure the accuracy and repeatability of calibration, you need to focus on the following four points:

- Regular Calibration: Conduct calibration regularly to maintain test accuracy.

- Use Certified Instruments: Ensure sensors and meters are traceable to international standards.

- Environmental Control: Perform calibration in a stable environment of (20±5)°C to prevent variations.

- Training: Train personnel thoroughly on calibration procedures and safety protocols.

Conclusion

The IPX9K Water Jet Impact Force Calibration Procedure is a crucial part in ensuring accurate, repeatable, and compliant testing of devices against high-pressure water jet . By following a structured calibration process and adhering to best practices, manufacturers and testing laboratories can confidently assess device robustness and meet industry certifications.

Regular calibration not only safeguards product quality but also enhances consumer trust and brand reputation. Whether you’re setting up a new testing facility or maintaining an existing one, meticulous calibration will keep your IPX9K testing rigorous and reliable.

AmadeTech provides different levels of IP waterproof testing equipment. If you have any questions or need a quote for equipment, please feel free to contact us to get a test solution.