IPX9K test is a waterproof level test item specified in IEC 60529, ISO 20653 and DIN 40050-9 standards. IEC 60529 is a test standard established by the International Electrotechnical Commission to determine the degree of protection provided by the enclosure of electrical equipment, while ISO20653 is a test standard established by the International Organization for Standardization for the degree of protection of electrical equipment on vehicles on the road against foreign objects, water and access. However, IPX9K is called IPX9 instead of IPX9K in the IEC60529 standard. It is a new test item added in the revised version in 2013. DIN40050-9 is a German national standard, and its content is basically the same as IOS 20653. A test item appears in several different test standards at the same time, indicating that it is highly accepted and authoritative. This post will give you a basic understanding of IPX9K testing.

What is IPX9K Testing?

IPX9K is a test for the highest level of waterproof performance for electronic equipment or electrical products. “IP” stands for “Ingress Protection”, X” indicates that there is no assessment of dust protection, and “9K” stands for the 9th level of protection, which is the spray of high-temperature and high-pressure water. Specifically, IPX9K testing simulates high-temperature and high-pressure water jets spraying at the specimen from different directions for a specified period of time. If the test passes, it means that the device can withstand the flushing and spraying of high-temperature and high-pressure water flow, ensuring its waterproof performance in harsh environments. It is especially commonly used in the fields of automobiles, industrial equipment, outdoor electronic products, etc.

The Significance of IPX9K Waterproof Testing

Verifying the protective capability of the product under extreme conditions

IPX9K water resistance testing evaluates a product’s ability to withstand extreme environmental conditions, specifically high-pressure and high-temperature water jets. By subjecting products to these extreme conditions, manufacturers can verify that the device will still function properly and prevent water ingress in real-world scenarios such as car washes, industrial cleaning, or heavy rain. This verification ensures that the product can maintain its integrity and performance in harsh environments, guaranteeing product reliability and durability.

Shortening product development cycle

Implementing IPX9K testing early in the product development process helps to quickly identify potential water-resistant defects. Finding and resolving these issues early can reduce the need for extensive redesigns later in the process. This proactive approach streamlines the development process, saves time, and speeds up time to market. Ultimately, robust testing such as IPX9K ensures that products meet quality standards efficiently, allowing companies to launch new innovative products faster and stay ahead of their competitors.

Enhancing product reputation and increasing consumer trust

Products that successfully pass the IPX9K waterproof test demonstrate their high quality and durability. When brands highlight this rigorous testing, consumers gain confidence in the product’s reliability, especially those who use their devices in demanding environments. Consistently delivering waterproof, rugged products can enhance your brand’s reputation, making customers more likely to choose your products over those of your competitors and fostering long-term loyalty.

Reducing warranty claims and saving cost in long term

By ensuring that their products are highly water-resistant through IPX9K testing, manufacturers can significantly reduce the likelihood of early failures due to water damage. Fewer warranty claims means lower costs for repairs, replacements, and after-sales service. Over time, this will save the company money, improve profit margins, and enhance the overall profitability of the product.

Obtaining the market access threshold, easier to carry out marketing activities

Many markets and industries require products to meet specific safety and quality standards before they can be sold. Obtaining IPX9K certification can serve as an important barrier to market entry, opening the door to new regions and new customer segments. Additionally, a recognized certification can strengthen marketing messages, increase credibility, and provide a competitive advantage, making it easier to market and sell products globally.

What Products Require IPX9K Testing?

Automotive electronics and components

Examples: Charging station nozzles/sockets for electric vehicles, battery pack seals, automotive sensors and lighting.

Benefits: Ensure functionality even after high-pressure cleaning such as car washing, improving durability and customer satisfaction.

Industrial equipment

Examples: Control panels, sensors and machines used in manufacturing plants.

Benefits: Protect sensitive electronic devices from water ingress during cleaning or in humid industrial environments, reducing downtime and repair costs.

Outdoor consumer electronics

Examples: Smartphones, tablets, digital cameras, outdoor speakers, etc.

Benefits: Ensure that the device remains waterproof during heavy rain, outdoor exposure or close-range high-pressure cleaning, improving product credibility.

Medical equipment

Examples: Portable medical devices and diagnostic equipment used in clinical or outdoor environments.

Benefits: Ensure safety and functionality, maintain sterility and performance standards even when exposed to water.

Agricultural equipment

Examples: Soil sensors, irrigation controllers and other electronic agricultural tools.

Benifits: Protect the equipment from the impact of clean water or heavy rain, ensuring stable operation and service life.

Test Means and Test Conditions for IPX9K

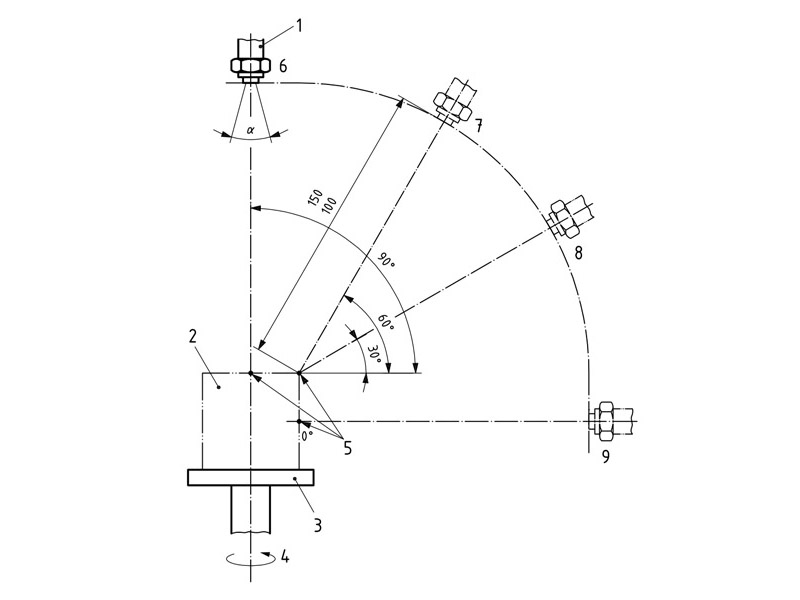

The test method of IPX9K is that the sample is fixed on a turntable rotating at 5 rpm, and 4 nozzles of specified size are arranged and positioned along the longitudinal plane at 0, 30, 60 and 90 degrees on one side of the sample to aim at the sample. The distance between the nozzle and the sample is kept at 100~150 mm. In theory, the 0-degree nozzle needs to be aimed at the midpoint of the sample’s endorsing cylinder facing the nozzle side, the 30-degree nozzle and the 60-degree nozzle need to be aimed at the upper edge of the sample’s endorsing cylinder facing the nozzle, and the 90-degree nozzle needs to be aimed at the center point of the top surface of the sample’s endorsing cylinder. Before the test, the test water needs to be heated to 80 ± 5 degrees Celsius. During the test, the water pressure is pressurized to about 8000 to 10000 kPa and sprayed out from the nozzles alternately at a flow rate of 14L/min to 16L/min. The spraying time of each nozzle is 30s, and the spraying order is 0 degree nozzle, 30 degree nozzle, 60 degree nozzle, 90 degree nozzle, until the end of the test.

IPX9K test diagram

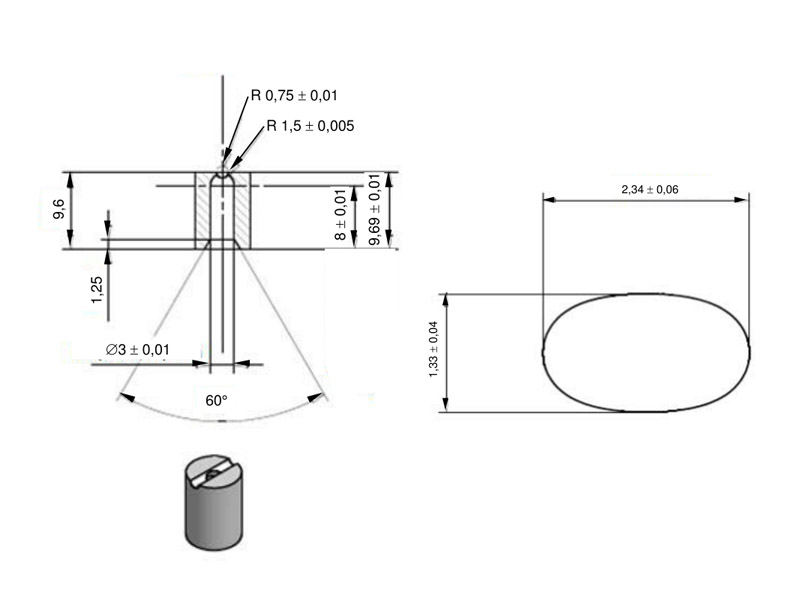

fan jet nozzle dimensions

| Test means description | Water flow rate | Water pressure | Water temperature | Exposure time |

| Sample fixed to the turntable rotating at 5 rpm is sprayed at 0°, 30°, 60°, 90° from fan jet nozzles at a distance of 100 to 150 mm | 15±1 L/min | Approx. 8000 to 10000 kPa | (80±5)°C

Deviating temperature may be agreed |

30 seconds per spray angle |

Test Equipment Used for the IPX9K Testing

For IPX9K testing, we recommend the high temperature and high pressure water jet test chamber from AmadeTech. The equipment has a fully enclosed test chamber made of 304 stainless steel. There is a door at the front of the chamber with a window for the operator to observe the inside of the chamber during the test. There is a rotating turntable in the center of the chamber for the operator to rotate and fix the sample, which can withstand a maximum of 50kg of sample. The height of the turntable can be freely adjusted according to the sample size to meet the spray distance specified by the standard.

A spray system consisting of 4 nozzles, brackets, water pipes, and adjustment devices is configured on the upper right side of the chamber. The fan jet nozzle is 2.34±0.06 mm x 1.33±0.04 mm. Under a 100x magnifying glass, it can be clearly seen that the nozzle’s surface finish is very good without any burrs or gaps. The size of each nozzle on the machine strictly complies with the relevant standards, and all errors are guaranteed to be within the relevant regulations and can pass third-party inspection. The position of the nozzle supports manual adjustment in the longitudinal and lateral directions to match different test sample sizes. The chamber is equipped with a lighting lamp and a sample power supply socket. The test device occupies a small area, is easy to operate, has no special requirements for the test site, and the test water is circulated during the test process, so it is very water-saving.

IPX9K Test Procedure

1) If required,first measure the impact force of the water jet with the calibration device to ensure that the impact force distribution is within 0.9N to 1.2N.

2) Use cable tiles, ropes or screw clamps to firmly fix the product on the turntable to prevent it from being washed off by water jets during the test.

3) Manually adjust the height of the turntable and the horizontal and vertical positions of the nozzles so that all four nozzles are aimed at the sample and keep a distance of 100 ~ 150 mm from the sample.

4) If the sample needs to be powered during the test, first connect the positive and negative power cables of the sample to the waterproof adapter plug we provide, and then insert the adapter plug into the sample power socket on the side of the test chamber. (Note that the sample operating voltage and power supply voltage must be consistent.)

5) Go to the human-machine interface of the machine, tap on the touch screen to turn on the sample power switch, turn on the turntable rotation switch to allow the sample to rotate in a single direction or alternately rotate in both directions, and set the test parameters, including the single spray time of a single nozzle such as 30s, the nozzle spray interval time, the number of cycles and other parameters. Finally, tap on the heating button to start heating the water.

6) After the test water is heated to (80±5)°C, tap on the “Start” button on the test interface to start the test. The nozzles will start spraying water in the order of 0-degree nozzle, 30-degree nozzle, 60-degree nozzle, and 90-degree nozzle. Each nozzle sprays water for 30 seconds until all sprays are completed and the machine automatically stops.

7) Stand on the side of the equipment and slowly open the door of the test box to prevent being scalded by the hot steam inside. Wait until the temperature in the box drops before removing the sample to determine the test results.

Final Thoughts

IPX9K waterproof testing plays a vital role in ensuring that electronic products can withstand extreme water exposure, especially high-pressure and high-temperature water jets. The significance of IPX9K waterproof testing is not limited to compliance with standards. It also provides manufacturers with a competitive advantage by verifying product reliability, shortening development cycles, and improving consumer trust, reducing overall costs. From automotive parts to outdoor electronics, many products benefit from this rigorous testing, which helps prevent costly failures and improve brand reputation. Understanding the relevant test methods, conditions, and equipment helps companies effectively meet industry standards. Ultimately, IPX9K testing in accordance with IEC 60529, ISO 20653, and DIN 40050-9 is an important guarantee for providing reliable, durable, and high-quality products in today’s demanding markets.

AmadeTech is a professional supplier of IP waterproof testing equipment. If you have any questions or need further information about IPX9K testing equipment, please feel free to contact us.